Specialty Gas Pressure Regulator Valve And Gas Changeover Manifold System | Stainless Steel High Purity Oxygen Nitrogen Helium Argon Gas Changeover Manifold And Gas Cabinet Manufacturer And Supplier

(Isstories Editorial):- Shenzhen, Guangdong Dec 4, 2025 (Issuewire.com) – In a significant stride forward for high-tech manufacturing and innovation, Shenzhen Jewellok Technology Co., Ltd., a renowned leader in the design and production of ultra-high purity (UHP) specialty gas pressure regulator valve and gas changeover manifold system, today unveiled the launch and expansion of its cutting-edge product portfolio. These advanced solutions are meticulously engineered to address the escalating demands of purity, safety, and operational efficiency in critical sectors such as semiconductors, new energy technologies, pharmaceuticals, biotechnology, and petrochemicals. As industries worldwide push the boundaries of technological advancement, Jewellok’s offerings stand out by providing unparalleled control over fluid and gas systems, ensuring that even the slightest contamination is eliminated to safeguard mission-critical processes.

More on Isstories:

- Jewellok Unveil Ultra-High Purity Gas Pressure Regulator And Gas Changeover Manifold for Precision Industries

- Vegas PBS Reinvents the Live TV Pledge Drive to Support Public Television

- Advanced Solutions Labeling Machine From China to be a Main Attraction at Russian Plastics and Rubber Exhibition

- Pioneering Global Energy Transition: Strategy of a China Future Leading Power Conversion System Exporter

- Famistar Incline Treadmill vs Walking Pad: Which Burns More Calories and Builds Endurance Faster?

The expansion comes at a pivotal time when global supply chains are increasingly reliant on high-purity components to maintain competitive edges. With the semiconductor industry alone projected to reach trillion-dollar valuations in the coming years, and emerging fields like hydrogen energy and photovoltaics experiencing explosive growth, Jewellok’s innovations are poised to become indispensable tools for engineers and manufacturers. By leveraging state-of-the-art materials and precision engineering, the company aims to reduce downtime, enhance yield rates, and lower overall operational costs for its clients across diverse applications.

At the heart of Jewellok’s expanded lineup are its UHP valves, regulators, fittings, and integrated gas systems, all crafted from premium 316L grade stainless steel. This material choice is no accident; 316L stainless steel is celebrated for its exceptional corrosion resistance and durability, making it ideal for environments where aggressive chemicals and gases are handled daily. To further elevate performance, Jewellok employs advanced electropolishing techniques, achieving ultra-smooth surface finishes of 5Ra or better. This process not only minimizes the risk of particle adhesion and bacterial growth but also ensures that fluid paths remain impeccably clean, free from contaminants that could compromise sensitive operations in cleanrooms or high-vacuum settings.

“Our expanded product lines represent a culmination of years of research and development, focused on delivering solutions that exceed industry standards,” said James Yuan, a key representative of Jewellok Technology. “In high-stakes fields where even microscopic impurities can lead to catastrophic failures, our commitment to innovation drives us to create ultra-high purity gas control systems that offer compact construction, high flow capacity, and unwavering reliability. By partnering with us, industries can achieve optimal performance, enhanced safety, and significant cost savings.”

Delving deeper into the product offerings, Jewellok’s Ultra High Purity Regulators are a standout feature of the expansion. Available in single-stage and dual-stage configurations, these regulators are specifically tailored for the semiconductor industry, where precise pressure control is paramount. Utilizing a negative feedback mechanism from the controlled pressure, they maintain stability even under fluctuating inlet conditions, ensuring consistent delivery of gases at the exact pressures required for processes like chemical vapor deposition (CVD) or etching. This precision helps manufacturers optimize their workflows, reducing waste and improving throughput in fabrication facilities.

Complementing the regulators are the Ultra High Purity Diaphragm Valves, which come in a variety of actuation types including electronic, pneumatic, manual, and air-actuated models. These valves are built to withstand extreme temperatures ranging from sub-zero to elevated levels and pressures up to several thousand psi, making them versatile for applications in harsh environments. Their design emphasizes fast response times–often in milliseconds–and minimal dead volume, which prevents gas trapping and ensures quick purging. This is particularly beneficial in pharmaceutical manufacturing, where sterile conditions must be upheld during drug synthesis, or in new energy sectors like battery production, where reactive gases need to be handled with utmost care.

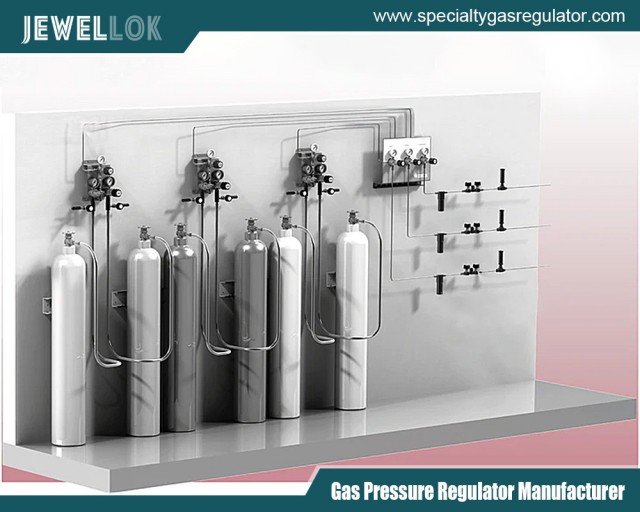

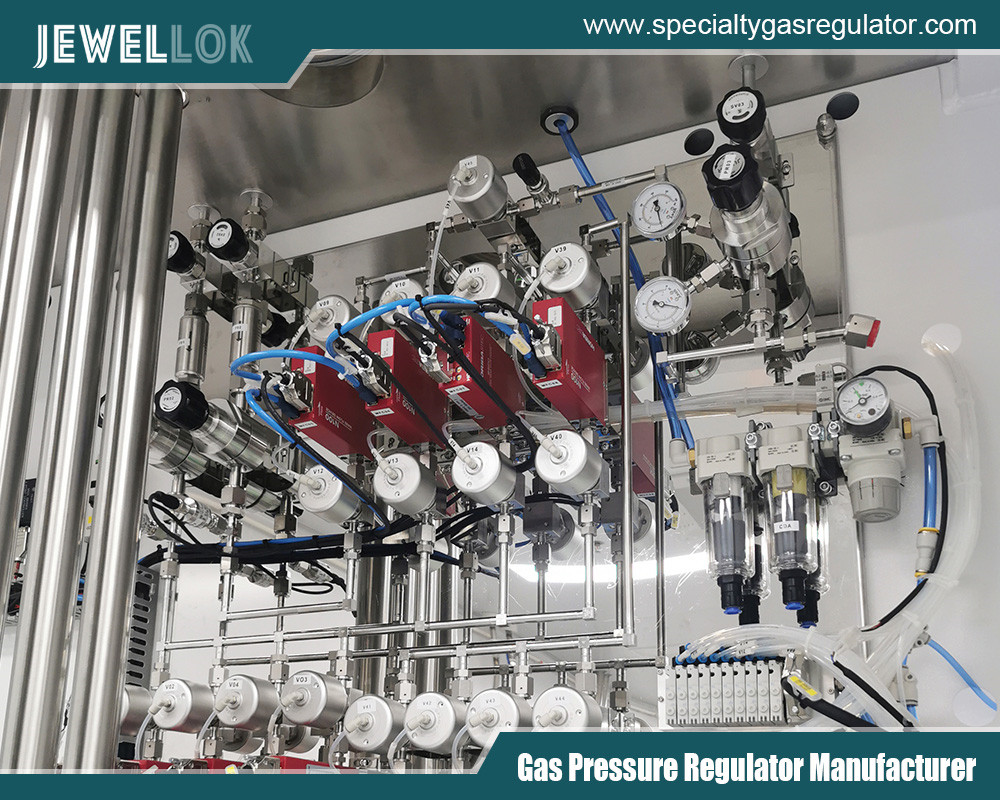

Jewellok’s Integrated Gas Systems further underscore the company’s holistic approach to gas management. These systems encompass fully automatic and semi-automatic gas cabinets (GC), bulk specialty gas systems (BSGS), valve manifold boxes (VMB), and valve distribution boxes (VDB), along with changeover manifolds. They are compatible with a wide array of specialty gases, including silane (SiH4), nitrogen trifluoride (NF3), ammonia (NH3), nitrous oxide (N2O), and hydrogen chloride (HCI)–gases that are staples in semiconductor fabrication, photovoltaic cell production, and hydrogen fuel cell development. By automating gas delivery and monitoring, these systems minimize human error, enhance safety through features like leak detection and emergency shutoffs, and support seamless integration into existing infrastructure. For instance, in a photovoltaic plant, where NF3 is used for chamber cleaning, Jewellok’s systems ensure reliable supply without interruptions, contributing to higher solar panel efficiency and yield.

Rounding out the portfolio are the Compression Tube Fittings, precision-manufactured to create leak-tight assemblies that endure the rigors of high-performance applications. These fittings are designed with advanced sealing technologies that provide superior grip and vibration resistance, preventing leaks even in dynamic systems. Their compatibility with various tubing materials and sizes makes them a flexible choice for custom setups in biotechnology labs or petrochemical refineries.

What sets Jewellok apart as a strategic partner is its ability to cater to a broad spectrum of high-tech industries. In semiconductors, where the push for smaller nodes demands ever-higher purity levels, Jewellok’s products help fabs achieve sub-10nm processes without defects. In the new energy domain, particularly hydrogen energy, the company’s regulators and valves facilitate safe handling of hydrogen gas, supporting the global transition to clean fuels. Photovoltaics benefit from precise gas control in thin-film deposition, while pharmaceuticals rely on contamination-free systems for API (active pharmaceutical ingredient) production. Even in emerging areas like quantum computing or advanced materials research, Jewellok’s solutions provide the foundational reliability needed for breakthroughs.

Beyond products, Jewellok offers a suite of value-added services, including custom design, assembly, CNC machining, and CAD/3D prototyping. This end-to-end capability allows clients to collaborate closely with Jewellok’s engineers to tailor components and systems to exact specifications. Whether it’s modifying a valve for a unique pressure profile or integrating a gas cabinet into a smart factory ecosystem, these services ensure that solutions are not just off-the-shelf but optimized for specific challenges. This customization has been key to Jewellok’s success in building long-term partnerships with global leaders in high-tech manufacturing.

The company’s emphasis on innovation is matched by its dedication to quality and sustainability. All products undergo rigorous testing for leak integrity, cycle life (often exceeding millions of cycles), and particle generation, ensuring they meet or surpass international standards like SEMI and ISO. By reducing particle emissions, Jewellok helps clients minimize environmental impact, aligning with global sustainability goals. Moreover, the high durability of these components translates to longer service life, reducing the need for frequent replacements and thereby lowering the carbon footprint of operations.

Looking ahead, Jewellok plans to continue investing in R&D to anticipate future industry needs. With advancements in AI-driven manufacturing and the rise of Industry 4.0, the company is exploring smart sensors and IoT integration into its gas systems for real-time monitoring and predictive maintenance. This forward-thinking approach positions Jewellok not just as a supplier, but as a collaborator in driving technological progress.

About Shenzhen Jewellok Technology Co., Ltd.

Shenzhen Jewellok Technology Co., Ltd. is a premier manufacturer of UHP specialty gas pressure regulator valve and gas changeover manifold system, control valves, and pressure regulators. With a focus on precision engineering and reliability, Jewellok provides industry-leading products for semiconductor, biotechnology, pharmaceutical, new energy, and petrochemical applications worldwide. The company is dedicated to delivering high-performance, cost-effective, and ultra-reliable fluid and gas control solutions to its diverse global market. For more information, visit www.jewellok.com.

Contact Info

James Yuan

Shenzhen Jewellok Technology Co., Ltd.

Building A3, No. 440, Hedong Village, Hengkeng, Guancheng Community, Guanhu Street, Longhua District, Shenzhen City, China

Phone: +86-13380377051

Email: [email protected]

Website: https://www.specialtygasregulator.com/

Shenzhen Jewellok Technology Co., Ltd

[email protected]

+8613380377051

Building A3, No. 440, Hedong Village, Hengkeng, Guancheng Community, Guanhu Street, Longhua District

https://www.specialtygasregulator.com/

This article was originally published by IssueWire. Read the original article here.