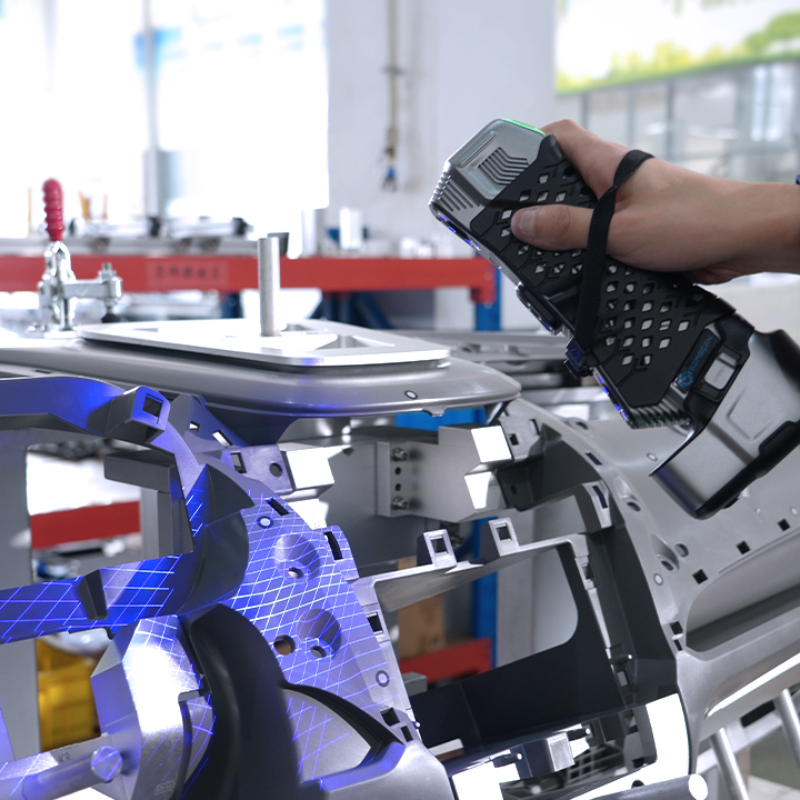

(Isstories Editorial):- Hangzhou, Zhejiang Dec 2, 2025 (Issuewire.com) – As manufacturers accelerate their adoption of digital measurement technologies, the demand for top rated 3D scanner software for inspection and analysis continues to rise across global industries. SCANOLOGY, a leading provider of comprehensive 3D solutions, is at the forefront of this transformation. Leveraging strong R&D capabilities and decades of engineering expertise, SCANOLOGY delivers metrology-grade hardware and software designed to meet the evolving needs of aerospace, automotive, heavy industry, healthcare, cultural preservation, and emerging digital fields. Through its advanced SCANOLOGY product line and its widely adopted 3DeVOK software suite, the company empowers enterprises worldwide with high-precision, portable, and intelligent 3D measurement solutions.

I. Precision, Speed, and Reliability — The Technical Foundation of SCANOLOGY’s Software

In industrial metrology, precision is non-negotiable. SCANOLOGY’s 3D scanning software ecosystem is built on a foundation of advanced algorithms engineered to deliver micron-level accuracy, even in complex and variable environments. By combining high-fidelity point cloud registration, multi-sensor fusion, and adaptive noise filtering, SCANOLOGY ensures that each scan captures true-to-life geometry with minimal data deviation.

More on Isstories:

- Vox Pop Branding Introduces The Amplify Project to Redefine How Small Businesses Fund Growth

- Bladder – Bowel Institute Appoints Jennifer Riad as Chief Marketing Officer to Lead National Brand Expansion

- AGII Establishes Intelligent Automation Framework to Support Adaptive Cross-Chain Web4 Systems

- Angela Svonavec Supports Expansion of Registered Texas Longhorn Program in Somerset County

- RedRock Compensation Consulting Launches to Help Growing Companies Build Smarter Pay Programs

Speed, another critical performance pillar, is optimized through streamlined processing pipelines capable of handling millions of data points per second. Whether used with SCANOLOGY’s industrial high-precision 3D scanners or its portable optical 3D scanners, the software processes dense 3D data at remarkable speeds without compromising measurement integrity. Operators can quickly transition from scanning to inspection, enabling faster decision cycles on the shop floor.

Reliability is strengthened through robust hardware-software compatibility. SCANOLOGY’s software suite is designed to remain stable in industrial environments where vibration, temperature variations, and dynamic lighting conditions can disrupt lesser systems. With intelligent error-correction features and redundant computation paths, SCANOLOGY ensures consistent measurement accuracy and stable system performance.

II. Automated Inspection and GD&T — Core Applications for Smart Manufacturing

A major driver behind the global adoption of SCANOLOGY’s solutions is the software’s powerful automated inspection engine, which transforms raw scan data into actionable dimensional insights. Manufacturers seeking to accelerate quality processes can fully or partially automate inspection workflows using SCANOLOGY’s GD&T toolkit, which includes:

- Feature extraction for complex geometries

- Deviation and tolerance analysis

- Edge and profile detection

- Geometric comparison against CAD models

- Automated pass/fail evaluation

These capabilities make SCANOLOGY a reliable platform for industrial sectors that rely on repeatable, compliant, and traceable measurement workflows.

In aerospace and automotive manufacturing in particular, automated GD&T interpretation significantly reduces the time required for checking form, orientation, profile, runout, and location tolerances. SCANOLOGY’s metrology tools ensure dimensional accuracy in mission-critical components such as turbine blades, structural frames, injection systems, die-cast components, additive-manufactured parts, and composite assemblies.

The software’s scripted automation further enables unattended batch inspection, reducing labor intensity and allowing engineers to focus on advanced decision-making. SCANOLOGY’s industrial automated 3D systems integrate seamlessly into production lines, enabling real-time inspection that keeps pace with continuous manufacturing.

III. User Experience and Integration — Designed for Usability and Efficiency

SCANOLOGY understands that metrology solutions must be both powerful and accessible. Its 3D scanning software is developed with a focus on ease of use, ensuring that operators–from entry-level technicians to expert engineers–can achieve optimal results with minimal training.

Key user experience features include:

- Intuitive interface layoutswith simplified navigation

- Guided workflows for scanning, alignment, inspection, and reporting

- Adaptive scanning modes for different materials and surfaces

- One-click CAD alignment and feature detection

- Real-time preview visualization for immediate feedback

- Multilingual interface support to serve global customers

SCANOLOGY’s strong integration capabilities allow seamless compatibility with industry-standard CAD and CAE platforms, including CATIA, SOLIDWORKS, Siemens NX, PTC Creo, AutoCAD, and more. This compatibility simplifies collaboration between design, engineering, and quality teams.

The software also supports direct connectivity to SCANOLOGY’s full hardware lineup–from portable 3D scanners to fully automated robotic 3D inspection cells–ensuring a unified operational ecosystem.

IV. Reporting and Data Visualization — Turning 3D Data into Real Value

The ultimate value of inspection data lies in how clearly it can be interpreted and acted upon. SCANOLOGY’s software delivers high-quality reporting functions designed to meet both technical and managerial needs.

These include:

- Color map deviation heatmapsfor intuitive understanding of dimensional variance

- Point-to-surface and point-to-CAD comparisons

- Tolerance zone visualization for GD&T evaluations

- Automated generation of PDF, Excel, and 3D interactive reports

- Customizable templatesfor different industries and project types

Visualization tools allow engineers to highlight critical areas such as warpage, shrinkage, machining errors, surface deviations, deformation after assembly, and additive manufacturing inconsistencies. With enhanced interpretation tools, decision-makers can reduce uncertainty and accelerate corrective actions.

Reports can be exported in multiple formats for quality documentation, regulatory compliance, and internal communication. This ensures that SCANOLOGY’s output aligns with global quality standards and industry certifications.

V. Industry Applications and Case Examples — Proven Market Impact

SCANOLOGY’s software ecosystem is trusted by companies across a diverse range of industries due to its reliability, accuracy, and versatility.

Aerospace

Manufacturers use SCANOLOGY for high-precision inspection of turbine blades, structural components, cast parts, and composite assemblies. The system reduces inspection time by up to 70% compared to manual measurement methods.

Automotive

Car manufacturers and suppliers rely on SCANOLOGY for stamping inspection, mold verification, welding analysis, assembly alignment, and EV component evaluation. The automated GD&T workflow ensures consistent compliance with strict global standards.

Heavy Industry & Machinery

SCANOLOGY’s high-accuracy scanning tools support large-scale inspection of machinery housings, engine blocks, gear trains, and fabricated components, improving operational uptime and reducing rework.

3D Printing & Digital Manufacturing

With support from 3DeVOK software, designers and additive manufacturing teams utilize SCANOLOGY for reverse engineering, surface reconstruction, artistic modeling, and production validation.

Art, Museums, and Cultural Preservation

SCANOLOGY’s color 3D scanning solutions capture detailed geometry and textures for digital archiving, restoration planning, and virtual exhibitions.

Medical & Biomechanics

Professional-grade scanning tools aid in prosthetic design, orthotic customization, surgical planning, and scientific research, supporting precision medicine initiatives.

Justice & Public Security

3DeVOK powers forensic modeling, accident reconstruction, and digital evidence preservation where accuracy and traceability are essential.

Across all these sectors, SCANOLOGY’s combination of advanced scanning hardware and intelligent software helps organizations reduce cost, improve productivity, and strengthen quality control.

About SCANOLOGY

SCANOLOGY is a global provider of comprehensive 3D measurement solutions, specializing in high-precision 3D scanners, automated inspection systems, and professional-grade 3D scanning software. With leading technologies in metrology, automation, and digitalization, SCANOLOGY and its 3DeVOK software brand serve industries ranging from aerospace and automotive to healthcare, cultural preservation, digital manufacturing, and public safety. The company is committed to innovation, reliability, and delivering smarter, more efficient measurement tools to the world.

For more information, please visit: https://www.3d-scantech.com/

This article was originally published by IssueWire. Read the original article here.