(Isstories Editorial):- Jinan, Shandong Dec 2, 2025 (Issuewire.com) – The pursuit of ultra-precision is the bedrock of modern advanced manufacturing. In sectors ranging from semiconductor fabrication and precision metrology to laser processing and high-end CNC machining, the stability and accuracy of the machine base are paramount. A flawed foundation translates directly to compounded errors in the final product.

This essential guide provides manufacturers and procurement professionals with the necessary framework to navigate the complex market and secure Top Rated Custom Granite Machine Bases, ensuring the long-term performance and reliability of their high-value equipment.

Understanding the Role of the Machine Base

More on Isstories:

- Lab Safety Redefined: Why DECENT Fume Hood Systems Are The Top Choice

- New Analysis on Housing Affordability, Showing Real Housing Costs Rose 27 Percent between 2020-2025

- The Ultimate Sourcing Guide: How to Spot High Quality Roller Tracks in a Crowded Market

- Flow and Form: Design Guidelines from a China Leading High-Flow Modified ASA Supplier KUMHO SUNNY

- KUMHO SUNNY’s Innovative Solutions: The Future of Automotive Plastics

The machine base is far more than a simple supporting structure; it is the critical component that dictates the geometry and dynamic performance of the entire system. Granite is the material of choice for ultra-precision applications due to its superior inherent characteristics: low thermal expansion coefficient, high damping capacity, and exceptional dimensional stability. These properties minimize the effects of temperature fluctuations and vibrational noise, which are the two primary causes of machining inaccuracy.

Key Performance Indicators for High-Quality Bases

When evaluating a custom granite machine base, buyers must focus on specific, quantifiable engineering metrics that define quality and performance. Compliance with international standards, such as DIN 876 or ISO standards, is non-negotiable; for ultra-precision equipment, a tolerance level better than Grade 00is often required, validated by precise metrology tools like laser interferometers. The quality of the raw granite, typically high-density black varieties, is crucial, as higher density and finer grain structure correlate with better dimensional stability. Furthermore, the base’s ability to dissipate mechanical vibration quickly, measured by a high damping ratio, is critical to preventing error propagation from cutting forces or motor movements. Finally, since most advanced machines require unique geometries, the supplier’s ability to integrate components like air bearings, linear motors, and guide rails directly into the granite surface with sub-micron accuracy is a defining feature of a top-rated base.

The Distinction Between Good and Inferior Bases

The primary difference between a top-rated, high-quality granite machine base and an inferior one lies not just in the final polish but in the entire manufacturing process and its foundation.

A superior base utilizes ultra-precision lapping, often multi-stage or robotic, as its core manufacturing method, in stark contrast to the simple grinding and manual scraping used for inferior products. This advanced process is underpinned by rigorous quality control, involving laser interferometer mapping and validation within strict temperature-controlled environments, providing buyers with traceable calibration reports. Conversely, lesser bases rely on basic dial gauge checks and limited environmental control. Material Quality is another key differentiator: top-rated bases are made from certified, naturally aged, high-density black granite, which is guaranteed to offer Guaranteed long-term dimensional stability due to proper stress relief. Inferior bases use lower-grade granite that may suffer from internal flaws, improper aging, and are therefore prone to “creep” or dimensional change over time. Finally, the Custom Integration capability is vital; a high-quality supplier ensures that precision-machined inserts (like T-slots or threaded holes) are integrated without compromising the overall flatness, while improper installation in inferior bases can cause localized material stress or unevenness.

The Hidden Costs of Compromising on Base Quality

Choosing an inferior granite base presents significant long-term risks that far outweigh any initial cost savings. The immediate and most profound impact is on Reduced Machining Accuracy. A base lacking the required flatness or dimensional stability directly contributes to systematic errors in the machine’s geometry, making it impossible to meet target tolerances for high-value components. Over time, inadequate damping capacity can lead to Premature Wear and Tear on expensive machine components, including linear guides, bearings, and spindles, resulting in increased maintenance costs and downtime. Furthermore, if the granite material was not properly aged to relieve internal stress, the base may experience Geometric Creep, a gradual but critical change in shape that renders the entire machine useless for ultra-precision work, requiring costly recalibration or complete replacement. Ultimately, a sub-standard foundation compromises product quality, increases scrap rates, and severely damages a manufacturer’s reputation for precision.

Selecting a Qualified Supplier: A Focus on Scale and Expertise

Identifying a supplier with the requisite technical depth and manufacturing capacity is critical. Look for companies that have a proven track record, operate under stringent quality management systems, and can handle extreme customization requirements.

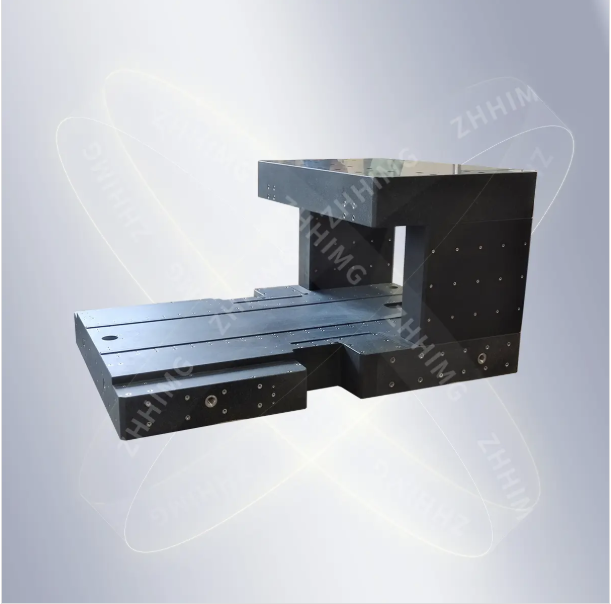

ZHHIMG’s Benchmark in Non-Metallic Ultra-Precision

As a recognized leader in this specialized field, Zhonghui Intelligent Manufacturing (Jinan) Co., Ltd. (ZHHIMG®) exemplifies the capabilities required to produce truly top-rated machine bases. Since the 1980s, ZHHIMG has focused on non-metallic ultra-precision manufacturing equipment, particularly large-scale granite components.

Their operational standards adhere strictly to international benchmarks, evidenced by concurrent certifications for ISO 9001 (Quality Management), ISO 14001 (Environmental Management), ISO 45001 (Occupational Health and Safety), and the EU CE mark. This multi-faceted certification guarantees a product manufactured not only to high technical specifications but also with environmental responsibility and worker safety in mind.

Technical and Production Advantages

ZHHIMG’s core advantages directly address the most demanding requirements of custom granite components: Extreme Scale Capability allows them to process exceptionally large components, manufacturing customized granite pieces up to 100 tons for a single unit or 20 meters in length. This capacity is vital for next-generation machines, such as those used in large-format display manufacturing or aerospace simulation. Furthermore, their High-Volume Processing capacity, reaching 10,000 sets per month, ensures both speed and consistency for large-volume orders without compromising the precision required for individual components. Beyond simple size and shape, ZHHIMG’s expertise extends to Comprehensive Customization, specializing in the complex integration of mechanical and electrical elements, including the precision machining of holes, slots, inserts, and structural light-weighting designs into the granite body, ensuring a seamless transition to the final assembly of the machine tool.

Conclusion: Investing in Precision

The decision to purchase a custom granite machine base is a long-term investment in precision, stability, and future manufacturing capability. By focusing on established engineering principles–specifically, tight tolerance grades, superior material quality, and the supplier’s verified capacity for large-scale, complex customization–buyers can confidently select Top Rated Custom Granite Machine Bases that will serve as the unwavering foundation for their most critical applications.

To learn more about custom granite components and ultra-precision manufacturing solutions, please visit the official website: https://www.zhhimg.com/

Zhonghui inteligent Manufacturing (Jinan) Group Co., Ltd.

[email protected]

http://www.zhhimg.com

This article was originally published by IssueWire. Read the original article here.