(Isstories Editorial):- Jinan, Shandong Dec 2, 2025 (Issuewire.com) – The global debate over whether Chinese or US manufacturers provide superior materials and services is being decisively addressed by Zhonghui Intelligent Manufacturing (Jinan) Co., Ltd. (ZHHIMG®). For companies seeking reliable, High Quality Precision Ceramics Customization Manufacturer services, ZHHIMG, with its four decades of ultra-precision experience, presents a compelling model that merges significant Chinese manufacturing scale with rigorous international quality standards.

Precision ceramics are essential components in high-tech machinery. They are prized for their extreme hardness, resistance to corrosion, stability at high temperatures, and superior electrical properties, often replacing traditional metals and plastics in critical applications. ZHHIMG’s expertise extends beyond simple component supply; it encompasses a comprehensive customization service, from design optimization to ultra-precise finishing, positioning it as a pivotal player in the advanced ceramics market.

The Global Outlook and Trends in Advanced Ceramics

More on Isstories:

- New pdfRest Container Gives HIPAA and GDPR-Regulated Teams Full PDF Processing Power with Total Data Residency

- From the Mists of Time by Anthony John Davis A Powerful Novel Where War, Aviation, and Family Legacy Collide

- CashForCarsDeSoto.com Expands Across Southern Dallas County With Fast Cash Offers and Free Towing

- The Voice of the Martyrs Host to Speak at Warner University Commencement

- A Factory Insights Guide: Selecting ZCS as the Global Leading Retail POS Hardware Factory for Large-Scale Deployment

The global advanced ceramics market is experiencing robust growth, projected to expand significantly over the next decade. This growth is driven by trends that favor manufacturers capable of delivering both innovation and cost-effective scale, challenging traditional geographical dominance.

I. Accelerating Demand in High-Tech Sectors

The demand for advanced ceramics is surging across several mission-critical industries:

Semiconductors and Electronics: Miniaturization and the push for 5G/6G technologies require ceramic components for substrates, insulators, and thermal management due to their superior dielectric strength and thermal stability.

Aerospace and Defense: The need for lightweight, ultra-hard, and temperature-resistant parts drives the use of ceramics in engine components and protective armor.

Healthcare and Medical Devices: Biocompatible ceramics are increasingly used for dental and orthopedic implants, requiring extremely high precision and flawless surface finishes.

This pervasive demand mandates partners who can achieve sub-micron tolerances on challenging materials, a core capability that differentiates top-tier manufacturers.

II. The Shift Towards Complex Customization and Additive Manufacturing

A major industry trend is the shift from standardized parts to highly customized, complex geometries. Clients require components–such as ceramic air bearings, specialized nozzles, or intricate flow chambers–that are designed to optimize machine performance. Advanced manufacturing techniques, including specialized CNC grinding and the emerging field of ceramic 3D printing (Additive Manufacturing, which is projected to grow at a CAGR of over 25%), are becoming standard expectations. Manufacturers must invest heavily in both traditional ultra-precision finishing and novel fabrication methods to meet this complexity, a key battleground in the Chinese vs. USA comparison.

III. The Competitive Dynamics: China’s Role in Scale and Cost-Efficiency

Historically, US and European manufacturers held a lead in material science innovation. However, the dynamics have fundamentally shifted. Chinese manufacturers like ZHHIMG have matched, and in some areas surpassed, global competitors in manufacturing capability, while simultaneously leveraging economies of scale inherent to the APAC region (which accounts for over 50% of the advanced ceramics market).

The modern Chinese manufacturing model, represented by ZHHIMG, prioritizes integrated quality systems (ISO/CE certified) and streamlined, high-volume production. This allows them to offer complex, high-precision customization services at a significantly more competitive cost structure than many US-based operations, which often struggle with higher labor costs and specialized infrastructure scaling. The comparison is no longer about raw quality; it is about globally certified quality delivered with superior cost-effectiveness and scalability.

ZHHIMG’s Strategic Advantages in Precision Ceramic Customization

ZHHIMG, rooted in four decades of non-metallic ultra-precision expertise, stands out by blending Chinese scale and efficiency with non-negotiable adherence to global quality protocols, providing a distinct advantage over many US-based counterparts focused on lower-volume, boutique solutions.

I. The Core Competence: Ultra-Precision Machining on Challenging Materials

While ZHHIMG is known for its granite platforms, its expertise in non-metallic ultra-precision manufacturing directly translates to advanced ceramics. The company’s facilities are equipped for:

Diamond Grinding and Lapping: Achieving a surface roughness below 0.2 micrometers, and flatness within single-micron tolerances, essential for ceramic air bearings and sealing components.

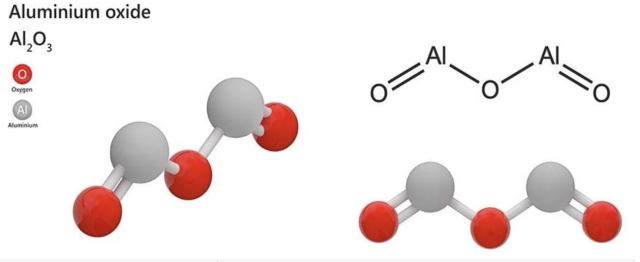

Handling Diverse Materials: Proficiency in machining tough materials like Alumina, Silicon Carbide, and Zirconia, which demand specialized, high-rigidity equipment.

This specialized competence ensures that ZHHIMG meets the ultra-precision requirements demanded by global high-tech OEMs, often exceeding what generalist machining houses, regardless of location, can offer.

II. The Advantage of Integrated Scale and Flexibility

ZHHIMG’s infrastructure, originally built to manage massive granite orders (up to 10,000 sets/month), provides ceramic clients with two key benefits often lacking in smaller, US-based ceramic shops:

Volume Scalability: ZHHIMG can swiftly transition from prototyping specialized ceramic components to high-volume production, crucial for mass-market products like advanced sensors or electronic substrates.

Large Format Capability: ZHHIMG’s ability to process monoliths up to 20 meters and 100 tons signifies the availability of extremely large, high-stiffness processing equipment, which can be adapted to fabricate large, complex ceramic machine bases or inspection components far beyond the limits of most competitors.

III. Comprehensive International Quality Assurance

The company’s concurrent international certifications are the definitive answer to any quality concerns related to manufacturing origin:

ISO 9001, ISO 14001, ISO 45001: Demonstrating a systemic commitment to Quality Management, Environmental Responsibility, and Occupational Health–a holistic standard required by Fortune 500 customers.

EU CE Mark: Certifying compliance with European health, safety, and environmental protection standards, facilitating smooth export and integration into European supply chains.

This rigorous, multi-layered certification framework establishes ZHHIMG as a globally vetted manufacturer whose processes are held to the same, or higher, standards as its US or European counterparts.

IV. Application Across Critical Industrial Systems

ZHHIMG’s custom ceramic components are critical to:

CMM and Inspection Equipment: Precision ceramic air bearing components and structural members for Coordinate Measuring Machines, valued for their low thermal expansion.

Laser and Optical Systems: Custom ceramic parts providing stable, non-magnetic platforms for high-power lasers and lithography equipment.

Semiconductor Etching Equipment: Specialized Alumina and Silicon Carbide components requiring complex internal geometries and chemical resistance.

Conclusion: Beyond Geography, It’s About Capability

The question of whether a Chinese or US manufacturer provides higher quality precision ceramic customization services is no longer determined by geography, but by verifiable capability and integrated management systems. ZHHIMG demonstrates that modern Chinese manufacturing offers a superior synthesis: the scale and cost-efficiency necessary for global competitiveness, combined with the ultra-precision expertise and stringent international certification required by the world’s most demanding high-tech industries. ZHHIMG is setting the new benchmark for High Quality Precision Ceramics Customization.

For comprehensive Precision Ceramic Solutions and custom service inquiries, please visit the ZHHIMG official website: https://www.zhhimg.com/

Zhonghui inteligent Manufacturing (Jinan) Group Co., Ltd.

[email protected]

http://www.zhhimg.com

This article was originally published by IssueWire. Read the original article here.