(Isstories Editorial):- Wuxi, Jiangsu Nov 24, 2025 (Issuewire.com) – The Cornerstone of Artisanal Scale: Engineering the Perfect Baguette Tray

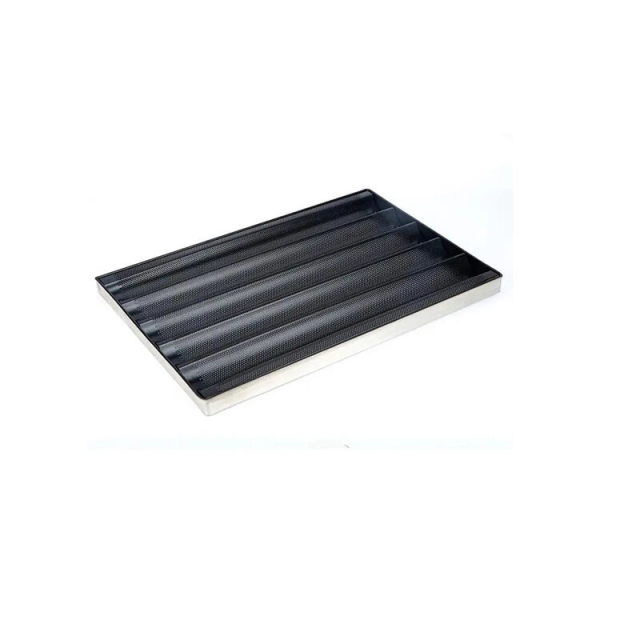

The baguette is perhaps the most iconic and demanding bread in the world. Its hallmark–a crust that is crisp, thin, and blistered, yielding to a light, open, and airy crumb–requires a perfect alchemy of heat, steam, and structure. In high-volume commercial and industrial bakeries, achieving this artisanal quality consistently, thousands of times a day, is impossible without specialized equipment. This is where Wuxi Hongbei Bakeware has distinguished itself, recognized as the China Top Baguette Tray Manufacturer. Hongbei doesn’t just manufacture metal; they engineer the thermal environment necessary for a perfect bake. The Baguette Tray, their specialized product, is the centerpiece of this operation, driving quality, efficiency, and scale in the booming market for specialty breads worldwide.

The Baguette Tray Revolution: Precision for the Perfect Loaf

More on Isstories:

- What Is a Free Puzzle Mobile Game That’s Actually Worth Playing? — Sudoku – Classic Sudoku Puzzle

- BestDates Explores the Future of Online Dating Etiquette in 2026

- iExotic Now Serving Dallas, Austin – San Antonio, TX

- Caregiver Burnout 101 by G. G. Geraldino Confronts the Hidden Crisis of Caregiving with Unfiltered

- Top Sign Company in San Jose, CA, Explores Cutting-Edge Digital Signage Trends for 2026

The modern Baguette Tray, often referred to as a Couche or Baker’s Tray, has evolved from a simple perforated sheet into a highly engineered thermal instrument. Its design, material, and coating directly dictate the final quality of the loaf, influencing crust development, bottom browning, and internal structure. The current industry outlook and future trends for this specialized piece of bakeware reflect the growing consumer demand for authentic, high-quality bread.

Engineering for Authenticity: Thermal Dynamics and Design

The primary function of the Baguette Tray is to replicate the effect of a traditional stone or hearth oven in a high-volume, automated setting. Achieving this is a complex engineering challenge, focusing on key design elements:

Optimal Perforation Density: The perforations are not merely for show; they are crucial for allowing moisture (steam) to escape rapidly from the dough’s underside during the critical initial phase of baking. This ensures a crisp bottom crust and prevents a gummy interior. The density and size of these holes must be finely tuned to the tray’s alloy and the oven type, an engineering decision that Hongbei bases on rigorous thermal testing.

Heat Transfer Management: High-quality baguettes require rapid and consistent heat application. Baguette Trays are engineered, often using perforated aluminum alloys, for maximum thermal conductivity. This ensures that the heat is evenly distributed across the entire surface and transferred efficiently into the dough, promoting consistent oven spring (the initial rapid rise).

Channel Profile and Shape Retention: The elongated, curved channels of the tray must provide perfect structural support to the dough while minimizing contact area. Crucially, the channels must maintain their precise curvature and dimension under continuous heat cycling to ensure that every single baguette has a uniform shape for automated slicing and packaging.

Industry Trends Driving Baguette Tray Innovation

The market for specialty breads is growing, forcing bakeries to demand more sophisticated equipment from manufacturers like Hongbei. Several key trends are driving innovation in Baguette Tray design:

The Sourdough Explosion: Sourdough and other high-hydration, acidic doughs are increasingly popular. These doughs are inherently more sticky and corrosive, requiring Baguette Trays with superior, acid-resistant non-stick coatings and robust construction to prevent material degradation over time.

Automation and Robotics: Industrial baguettes are increasingly handled by automated systems for scoring, loading, and depanning. This demands that Baguette Trays maintain absolute dimensional stability. Any warping, bowing, or variation in channel width can lead to catastrophic line stoppages, underscoring the necessity of Hongbei’s background in precision manufacturing.

“Clean Label” Baking: Bakeries are reducing or eliminating release oils and dusting flour to meet consumer demands for simpler ingredients. This shifts the performance burden entirely onto the Baguette Tray coating, necessitating ultra-durable, highly reliable non-stick surfaces that offer perfect release without chemical assistance, cycle after cycle.

The Future of Baguette Tray Technology

Looking forward, the Baguette Tray will evolve from a mechanical tool into an integrated component of a smart factory system, driven by data and advanced materials.

Integrated Tracking: Future Baguette Trays may incorporate passive tracking technologies (like hardened RFID tags or laser-etched codes) into their construction. This would allow bakeries to track the performance history, cleaning cycles, and expected end-of-life for every individual tray, moving from reactive maintenance to predictive asset management.

Advanced Composite Materials: While aluminum is dominant, manufacturers are exploring high-performance metal alloys and even composite materials that offer superior heat retention and structural memory, further enhancing the hearth-like baking effect while reducing the overall weight of the tray for easier handling by automated systems.

Custom Venting for Regional Climates: As global bakeries standardize production, the need for region-specific trays grows. A bakery operating in a high-humidity environment may require a tray with more aggressive perforation/venting than one operating in a dry climate. Hongbei’s ability to offer bespoke OEM/OED services will be critical for providing these environmentally tailored solutions.

Wuxi Hongbei Bakeware: Precision Manufacturing and Partnership

Wuxi Hongbei Bakeware’s leadership as a China Top Baguette Tray Manufacturer is a testament to its successful merger of 16 years of experience in precision manufacturing with the specialized needs of the food industry. This background allows them to deliver not just products, but engineered solutions.

Core Strengths and Strategic Services

Hongbei’s competitive advantage lies in its comprehensive approach, offering comprehensive OEM/OED services that turn complex client specifications into reliable products. This is essential for the custom nature of high-end bakeware:

R&D Collaboration: For a client seeking to launch a new specialty bread, Hongbei acts as an R&D extension. They utilize CNC prototyping and rapid tooling to quickly produce and test new Baguette Tray designs, ensuring the pan’s thermal profile and structural integrity meet the client’s exact product specifications before mass production begins.

Material Science Expertise: Hongbei’s experience across various manufacturing fields gives them a sophisticated understanding of metallurgy and coating application. This ensures they select the ideal alloy–balancing weight, durability, and conductivity–and apply the perfect non-stick coating thickness to withstand continuous industrial cleaning without failure.

Baguette Tray Applications and Client Success

The Baguette Tray is a specialized tool, and its application often involves solving specific thermal and structural problems for large, sophisticated clients.

Application Scenario: Hongbei’s Baguette Trays are used globally by industrial bakeries and large frozen dough producers who require a perfect, uniform crust on par-baked baguettes intended for final baking in retail outlets. Consistency in browning and size is critical for the client’s brand image.

Hypothetical Client Case: A major European frozen dough producer needed to reduce the baking time of their par-baked baguette line to boost throughput without sacrificing crust quality. Hongbei analyzed the client’s oven specifications and designed a Baguette Tray using a proprietary, high-gauge aluminum alloy with a custom perforation pattern. This engineered solution significantly increased the initial heat transfer rate, reducing the required baking time per batch by 8%, resulting in a massive increase in annual production capacity for the client.

Hongbei’s ability to deliver engineered longevity and solve complex production challenges is the hallmark of a China Top Baguette Tray Manufacturer, solidifying its role as an indispensable partner in the global artisanal bread movement.

To explore their full range of precision Baguette Trays and comprehensive OEM/OED services, please visit their official website: https://www.wxhongbei.com/

Wuxi Hongbei Bakeware Co., Ltd.

[email protected]

+86 510 8283 1000

7 Yuansheng Street, Xishan District, Wuxi CN 214107

https://www.wxhongbei.com/

This article was originally published by IssueWire. Read the original article here.