(Isstories Editorial):- Luoyang, Henan Nov 24, 2025 (Issuewire.com) – In industrial and high-tech fields, selecting the right materials is crucial to ensuring the long-term stable operation of equipment. Especially in high-temperature environments, conventional materials often cannot meet the rigorous performance requirements. Both tungsten heating elements and tungsten twisted wire, with their outstanding high-temperature resistance, strength, and electrical conductivity, have become the preferred materials for various critical applications. Whether as heating elements or resistance wires, tungsten’s unique advantages offer long-lasting and durable solutions for customers.

Why Choose Tungsten Heating Elements?

Tungsten heating elements, as a high-temperature heating material, are widely used across various industries, particularly in equipment that requires high-temperature environments. Tungsten itself has the highest melting point (up to 3422°C), making it an ideal material for high-temperature heating, and its high-temperature resistance ensures that tungsten heating elements can operate stably in many extreme temperature conditions without degradation.

More on Isstories:

- Immigrant Entrepreneurship in America by Gorm Tuxen Achieves #1 Amazon Bestseller Status

- Colle AI Formalizes Strategy Around Cross-Chain Asset Versioning Infrastructure.

- Imagen Network Sets Forth Multi-Perspective Rendering Initiative for Immersive Asset Creation

- Apolosign Digital Wall Calendar Tackles “Proxy Parenting” in U.S. Homes

- 25 Countries for Solo Travelers to Discover Themselves

The advantages of tungsten heating elements include:

Exceptional High-Temperature Endurance: Tungsten maintains its structural integrity at high temperatures, preventing material degradation and making it ideal for applications such as furnaces and heat treatment equipment.

Long-Term Durability: With high strength and hardness, tungsten heating elements can remain reliable even after long-term use in high-temperature environments, reducing replacement and maintenance costs.

Excellent Electrical Conductivity: Tungsten heating elements effectively conduct electricity, making the heating process more efficient and ensuring even temperature distribution, which enhances production efficiency.

Energy Efficiency: Due to tungsten’s high electrical conductivity, it can more efficiently convert electrical energy into heat, helping reduce energy consumption and meeting modern industry’s energy-saving requirements.

Tungsten heating elements are widely used in furnaces, heating tubes, gas heaters, and electronic equipment heating elements, providing efficient, stable, and long-lasting heating solutions.

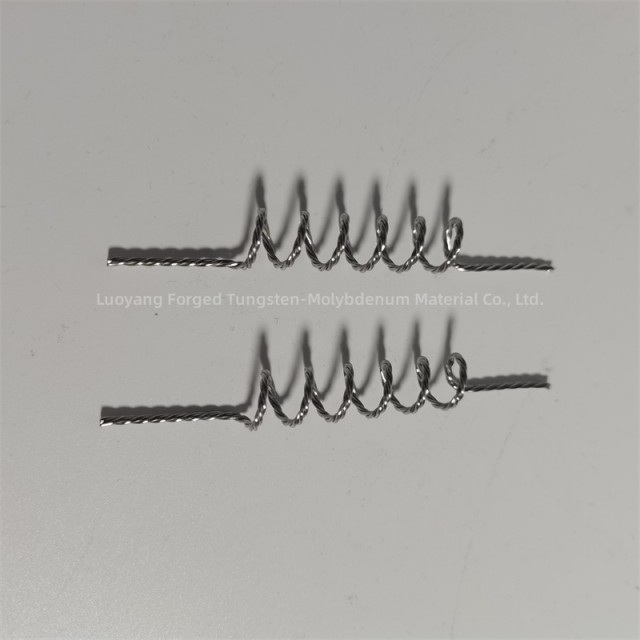

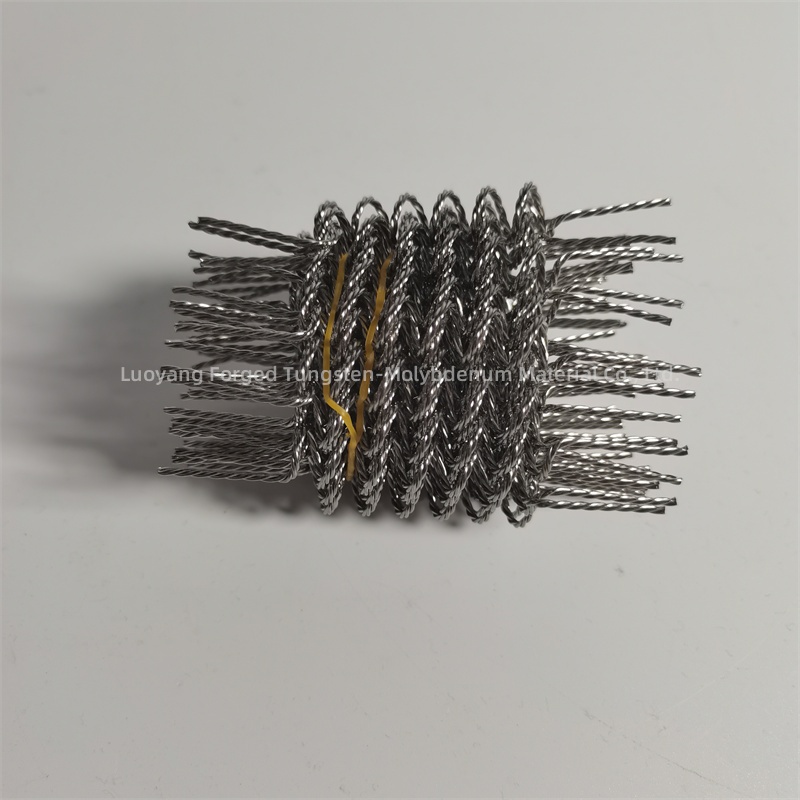

Tungsten Twisted Wire: A Versatile High-Temperature Material

Similar to tungsten heating elements, tungsten twisted wire is also widely used in high-temperature and corrosion-resistant environments due to its exceptional strength and high-temperature stability. Tungsten twisted wire is made by twisting multiple tungsten filaments together, which enhances strength and tensile resistance, making it suitable for applications requiring high mechanical and electrical performance.

Applications of tungsten twisted wire include:

High-Temperature Resistance Heating: Tungsten twisted wire, with its excellent conductivity and high melting point, is commonly used in various resistance heating elements, such as electric heaters and heating wires.

Electron Beam Welding: Tungsten twisted wire plays a vital role in electron beam welding, functioning at extremely high temperatures while providing strong electrical current and heat.

Aerospace: With its high strength and stability at high temperatures, tungsten twisted wire is widely used in high-performance components in the aerospace industry, especially in engine parts and high-temperature environments.

Metallurgy: Tungsten twisted wire is used in high-temperature furnaces in the metallurgy industry, withstanding the extreme heat of the smelting process and supporting equipment and machinery operations effectively.

Comparing Tungsten Heating Elements and Tungsten Twisted Wire

Although tungsten heating elements and tungsten twisted wire differ in their applications, they share similar core advantages–high temperature resistance, strength, and good electrical conductivity. The choice of which product to use depends on your specific needs and application scenario.

Tungsten heating elements are typically used in applications where uniform heating is required, such as furnaces and heating elements. Their primary advantage lies in their excellent current conduction and heating efficiency.

Tungsten twisted wire, on the other hand, is better suited for applications that require higher mechanical strength, temperature stability, and corrosion resistance, such as electron beam welding, aerospace applications, and high-temperature resistance heating.

Why Choose Us?

When choosing tungsten heating elements or tungsten twisted wire, quality and reliability are the most important considerations. As a professional tungsten product manufacturer, we are committed to providing customers with high-quality, high-performance tungsten heating elements and tungsten twisted wire to ensure long-term, stable performance in extreme environments.

Our tungsten heating elements and tungsten twisted wire feature:

High-Temperature Stability: Every piece of tungsten wire is designed to perform reliably in extreme temperatures, ensuring your equipment operates smoothly for years.

Customization Services: Whether you need specific lengths, diameters, or twisting patterns, we offer tailored solutions to perfectly match your applications.

Excellence in Customer Support: We have a dedicated technical team ready to assist you throughout the customization process, from product selection to installation, ensuring optimal performance of your equipment.

Luoyang Forged Tungsten-Molybdenum Material Co., Ltd.

[email protected]

86-15138768150

No. 102, Building 33, Phase II of Zhongde Industrial Park, Yibin District, Luoyang City, Henan Province

https://www.forgedmoly.com/

This article was originally published by IssueWire. Read the original article here.