(Isstories Editorial):- Xiamen, Fujian Nov 23, 2025 (Issuewire.com) – FILTECH 2026 will confirm that the future of filtration will be defined by precision, sustainability, and intelligent systems. The firm’s presence at the event will demonstrate that it is not merely a follower of these trends but a key driver of innovation in the global market. A national high-tech enterprise, the company will be committed to ongoing research and development to address the most complex filtration challenges facing the world today. The company’s dedication to engineering excellence, its robust quality management systems, and its mission to build global partnerships will position it as a leader in creating a more efficient and sustainable future.

At FILTECH 2026, Xiamen Citius Filter Media Technology Incorporated Company will demonstrate its leadership among Global Leading Filter Cloth Suppliers by showcasing innovations that will directly address the filtration industry’s most pressing trends. Held in Cologne, Germany, from June 30th to July 2nd, 2026, the event will serve as a crucial platform where the company, a national high-tech enterprise, will stand out for its pioneering approach to three core areas: the pursuit of greater precision, a commitment to sustainability, and the integration of intelligent automation. Its presence will be a clear testament to China’s advanced manufacturing capabilities on the global stage.

The Three Core Trends that FILTECH 2026 Will Highlight

More on Isstories:

- The Rise of Zero-Click Search: How Brands Are Winning Without Clicks

- Global Filter Cloth Suppliers Will Unveil Innovations at FILTECH 2026 in Cologne

- The Essential Guide to Choosing the Right Socks Printer Manufacturer

- Travis McIntyre, Recognized by BestAgents.us as a 2025 Top Agent

- Goldman and Young Chooses BatchMaster ERP to Streamline Manufacturing and Scale Operations

FILTECH 2026 will be defined by a shared vision for the future of filtration–one that is smarter, more efficient, and environmentally responsible. The solutions on display will represent revolutionary steps forward, not just incremental improvements.

Trend 1: The Revolution in Filtration Precision

The global demand for high-purity products in pharmaceuticals, fine chemicals, and new materials will drive a revolution in filtration precision. Traditional filter media will no longer be sufficient to capture increasingly fine particles at a high volume. Attendees at FILTECH 2026 will see a clear shift towards technical fabrics engineered at the micron and even sub-micron levels. This will require filter media with highly uniform pore sizes and superior structural integrity, capable of withstanding extreme pressure without compromising performance. The focus will move from simple particle capture to sophisticated dewatering that will ensure exceptionally low cake moisture and high filtrate clarity.

Trend 2: Environmental Protection and Sustainability

Sustainability will transcend buzzword status to become a core design principle for new filtration products. The industry will move away from disposable, single-use media towards durable, long-lasting solutions that will reduce waste and minimize a company’s environmental footprint. Manufacturers will prioritize materials and designs that not only improve filtration efficiency but also will reduce energy consumption during processes like dewatering and drying. The seamless release of the filter cake and easy cleaning of the filter media will be considered essential features, as they will directly impact operational efficiency and resource utilization, aligning economic goals with environmental responsibility. This expertise in high-performance dewatering will establish the firm as a China Best Dewatering Equipment Exporter.

Trend 3: Intelligence and Automation

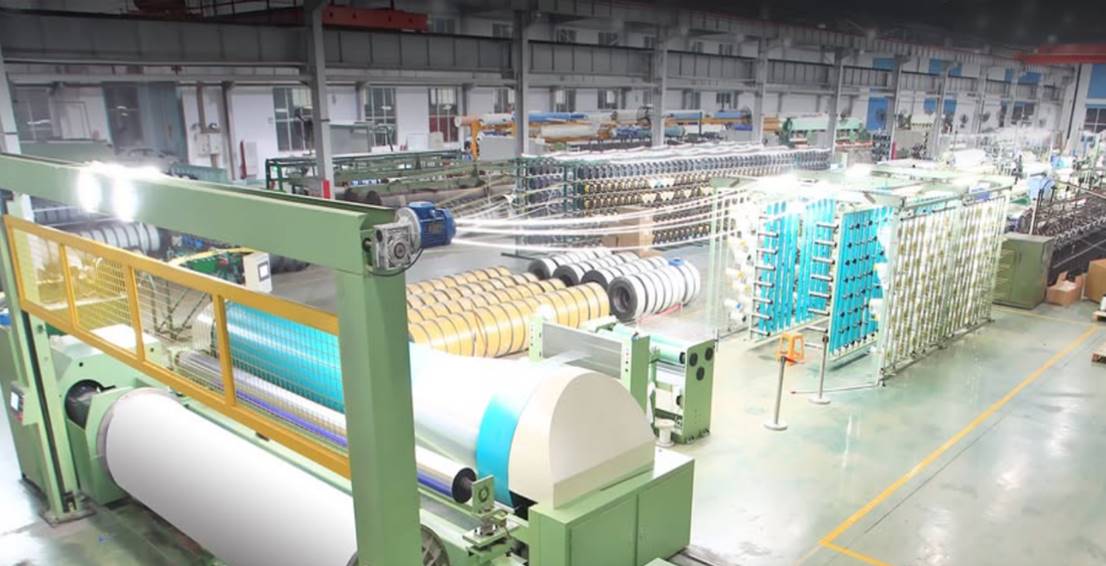

The integration of filtration systems into smart, automated production lines will be a prominent theme at FILTECH 2026. This shift will demand filtration media that can operate reliably and consistently within automated dewatering equipment. The efficiency gains from this trend will be transformative, as they will reduce manual labor, minimize downtime, and will enable real-time process monitoring. As a China Leading Filter Belt Exporter, the firm will showcase materials with enhanced tracking, anti-static properties, and superior wear resistance, ensuring seamless, uninterrupted operation in highly automated environments. The future of filtration will be one where the filter media is an intelligent component within a larger, interconnected system.

A Leading Practitioner of “Made in China”

A national high-tech enterprise and the drafting unit of the belt filter belt industry standard, the firm will demonstrate how it is not only keeping pace with these trends but also actively pioneering them. This commitment will position the company as a Global Leading Filtration Equipment Manufacturer.

Precision and Purity: The company’s mono-multifilament hybrid weaving technology will directly address the trend toward higher filtration precision. By combining the strength of monofilament fibers with the fine-particle retention of multifilament fibers, the firm will create a filter fabric with a highly uniform pore structure. This will ensure a superior level of filtrate clarity and a product purity that will be critical for sensitive industries.

Sustainability by Design: In line with the sustainability trend, the company’s products will be engineered for exceptional durability and dewatering efficiency. The company’s proprietary calendering process will create a smooth surface on the filter cloth, enabling a clean and easy cake release. This feature will not only reduce water consumption during cleaning but also will extend the lifespan of the filter media, minimizing waste and operational costs for clients.

Enabling Automation: The company’s advanced process mesh belts and filter fabrics will be designed to be a reliable and integral part of automated filtration equipment. Their robust construction and consistent performance will ensure smooth operation in continuous systems.

Real-World Applications: Tailored Solutions for Diverse Industries

The firm’s commitment to quality and innovation will be demonstrated through its successful application across a wide range of industries. The company’s expertise in filter material R&D, combined with years of industry experience, will allow it to provide tailored solutions that will address specific operational challenges and will support the parallel development of environmental protection and efficient production.

Environmental Protection and Resource Recycling: In sectors like sand washing and domestic sewage treatment, high-performance industrial filter cloth will be crucial for efficient solid-liquid separation. The firm’s solutions, particularly durable nylon monofilament filter cloths, will improve the recycling rate of sand washing wastewater, will reduce sludge treatment costs, and will ensure efficient, stable mud-water separation.

Chemical and Alumina Processing: The efficient dewatering of red mud will be a crucial step in the alumina industry. The company will provide reliable filter cloth solutions that will significantly improve dewatering efficiency, reduce waste disposal costs, and minimize environmental impact. Similarly, in the brick industry, high-quality filter cloth will play an irreplaceable role in calcium oxide processing, improving filtration efficiency, reducing production costs, and enhancing equipment service life.

Specialized Industrial Processes: The firm’s industrial filter cloths and mesh belts will play key roles in the pulp pressing process in paper mills, where they must meet demanding requirements for filtration accuracy, strength, abrasion resistance, and cleanability to ensure efficient production. In pharmaceutical intermediate production, the filter cloth will be a core component that, with professional technical support, will help improve the stability, compliance, and economic efficiency of the process. For modern breweries, the filter cloth for plate and frame filter presses will be key to achieving efficient, stable, and clean wort extraction, directly impacting the clarity and taste of the final beer.

Conclusion: Creating the Future Together

FILTECH 2026 will confirm that the future of filtration will be defined by precision, sustainability, and intelligent systems. The firm’s presence at the event will demonstrate that it is not merely a follower of these trends but a key driver of innovation in the global market. A national high-tech enterprise, the company will be committed to ongoing research and development to address the most complex filtration challenges facing the world today. The company’s dedication to engineering excellence, its robust quality management systems, and its mission to build global partnerships will position it as a leader in creating a more efficient and sustainable future. To learn more about the company’s innovative products and global solutions, please visit our website at https://en.citius-filter.com

Contact us: [email protected]

Xiamen Citius Filter Media Technology Incorporated Company

[email protected]

86-13950107241

No. 16-22 Chunfeng East Road, Xiang’an Torch High tech Zone, Xiamen City, Fujian Province, China

https://en.citius-filter.com/

This article was originally published by IssueWire. Read the original article here.