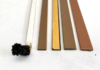

(Isstories Editorial):- Tianjin, China Nov 24, 2025 (Issuewire.com) – In modern building safety practice, ensuring robust fire resistance while maintaining construction efficiency is essential. China Intumescent fireproof sealing strips have emerged as a pivotal technology, balancing high fire resistance with practical installation features. These strips expand when exposed to heat, sealing gaps and preventing the passage of flames and smoke, all while accommodating architectural tolerances and movement. The result is a safer enclosure that still respects tight project timelines and budget constraints, delivering significant value beyond conventional sealing approaches.

The first line of defense in this approach is a well-engineered sealing system that integrates seamlessly with doors, windows, and curtain walls. When heat is detected, the intumescent material swells to fill joints, forming an insulating barrier that slows heat release and smoke propagation. This mechanism helps protect occupants and critical infrastructure, while enabling safer, more controlled evacuation. The practical benefits extend to faster installation, reduced assembly time, and simplified on-site adjustments, all of which contribute to lower total project costs and improved lifecycle performance.

From a project economics perspective, the upfront premium for high-performance sealing strips can be offset by substantial long-term savings. The enhanced fire protection reduces the risk of costly incidents and insurance exposure, while the improved energy performance associated with effective sealing can lower cooling loads and operational costs. Moreover, durability and resistance to environmental factors minimize maintenance and replacement needs, supporting a favorable return on investment over the life of the building.

More on Isstories:

- Beyond Traditional Sealing: How Intumescent Fireproof Sealing Strips Balance Fire Resistance Limits-Ease of Construction

- High-Performance Tungsten Heating Elements and Tungsten Twisted Wire: Ideal Choices for Industrial Applications

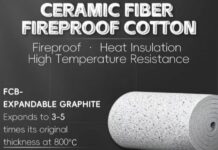

- Ceramic Fiber Fireproof Cotton: Advancing High-Temperature Insulation and Fire Safety

- Why does Famistar lead the best treadmill deals in Black Friday 2025?

- Wuxi Hongbei Bakeware: China Top Baguette Tray Manufacturer

Tianjin Junyihao Technology Co., Ltd. was established in 2014, mainly focusing on fireproof materials, intelligent door and window opening systems, and can provide customers with complete products and solutions. Our products have strong fire resistance, durability, and high efficiency; It can meet the characteristics of fire prevention, high temperature resistance, safety, and barrier free automation. This background underlines a broader industry trajectory toward integrated safety systems that fuse passive fire protection with active safety controls. Junyihao’s experience in both advanced materials and intelligent opening systems enables the delivery of customized, system-level solutions that align with contemporary design and safety requirements. The company’s capability to couple high-performance components with smart automation exemplifies how modern projects increasingly demand cohesive safety ecosystems rather than isolated products.

In the realm of materials, the industry continues to push for coatings and strip formulations that deliver predictable expansion behavior, stable adhesion, and longevity under diverse service conditions. Advances in chemistry and processing have yielded sealing strips that remain reliable through repetitive thermal cycles, resist degradation from environmental exposure, and maintain tight seals throughout the service life. These capabilities translate into safer joints, improved indoor air quality, and reduced risk of thermal bridging and smoke infiltration in high-occupancy or mission-critical facilities.

Equally important is the trend toward sustainable construction and green building practices. Fireproof sealing solutions are increasingly evaluated for their environmental footprint, including low VOC emissions, recyclable components, and compatibility with circular supply chains. Manufacturers that prioritize environmental stewardship alongside performance are better positioned to meet evolving certifications and stakeholder expectations, while continuing to deliver the high safety standards required by modern infrastructure.

Industry participation and case studies further illustrate the impact of advanced sealing technologies. Exhibitions and technical demonstrations provide a platform to compare performance data, validate installation methodologies, and build confidence among architects, engineers, and facility managers. Real-world deployments–ranging from high-rise office towers to critical transportation hubs–show how intelligent sealing strategies can contribute to safer, more resilient buildings with measurable improvements in energy efficiency and occupant safety.

Core advantages of leading intumescent sealing strips include: rapid, predictable expansion under heat to form a solid barrier; compatibility with a broad range of substrates including metal, glass, and composite materials; resilience to moisture and environmental aging; and straightforward installation that supports quick project execution and easy retrofits. When combined with compatible fire-rated substrates and protective coatings, these strips become integral to a holistic approach to fire safety, ensuring that both envelope integrity and internal compartmentalization are maintained under fire exposure.

Industry benchmarks emphasize not only raw performance but also traceability and certification. Independent testing confirms adhesion, elasticity, expansion rate, and fire resistance duration, while third-party verification assures consistency across production lots. For project teams, this means reduced procurement risk and smoother regulatory pathways, enabling faster adoption of best-in-class sealing solutions across markets.

In conclusion, Beyond Traditional Sealing reflects a growing recognition that fire resistance and construction convenience can coexist without compromise. High-performance intumescent sealing strips deliver strong protection against fire and smoke while supporting efficient, cost-effective construction and retrofit projects. For organizations seeking a trusted partner with proven capabilities in fireproof materials and integrated safety systems, Junyihao offers a comprehensive portfolio, technical support, and a global capability to tailor solutions to project needs.

To learn more about Junyihao’s full range of fireproof and intelligent building solutions, please visit the company website at https://jyhaotech.com/

This article was originally published by IssueWire. Read the original article here.