(Isstories Editorial):- Xiamen, Fujian Nov 16, 2025 (Issuewire.com) – In the global food sector, safety, quality and compliance are not negotiable. Packaging can have a significant impact on everything from the freshness of a product to consumer confidence. Food bags with gussets are very popular. But how can you tell the difference between a good and great bag? BRC is a powerful and unique certification. BRC certification ensures that a product meets the highest quality standards. This gives brands and consumers the confidence they need. BRC certification can be a great indicator when you’re looking for the Best Gusset Food Bags. It shows a commitment to quality and reliability.

Yinshili Packaging, a seasoned veteran in the Chinese domestic market and a dynamic player on the global stage, understands this at its core. The company has built a solid reputation over the past six years and is now expanding its global reach with advanced technology, an experienced team, and a commitment to international standards such as BRC. This article will explore what BRC certification means for gusset bags, the latest trends in food packaging, and how Yinshili Packaging, a Future Leading Gusset Food Bags Company, is uniquely equipped to meet the needs of a modern and discerning market.

What is BRC Certification?

More on Isstories:

- Social Media Creator Destiny (@oxdessyxo) Surpasses 1.5 Million Followers on Instagram

- Elizabeth Fraley Champions Confidence and Individual Growth Through Kinder Ready

- What Is a Free Puzzle Mobile Game That’s Actually Worth Playing? — Sudoku – Classic Sudoku Puzzle

- BestDates Explores the Future of Online Dating Etiquette in 2026

- iExotic Now Serving Dallas, Austin – San Antonio, TX

BRC Global Standards (Brand Reputation Through Compliance), is a system of food safety management that has been benchmarked and recognized globally. Specifically, the BRCGS Packaging Materials standard is a stringent framework that ensures packaging materials–especially those that come into direct or indirect contact with food–are manufactured to the highest possible standards. BRC certification of a gusset-style bag requires that the manufacturer demonstrate complete control over all aspects of production.

Hazard and Risk Management: At the core of BRC certification is a robust Hazard Analysis and Critical Control Points (HACCP) system. It involves identifying hazards from the raw material source to the final seal process and implementing controls that mitigate them. This could include ensuring that the raw resin used in a gusset bag is food-grade, preventing contamination during production, and checking the integrity of heat seals.

Quality Management Systems: BRC demands a documented and detailed quality management system. This includes everything from supplier approval to traceability and non-conformance management. This holistic approach builds a culture of quality and ensures that every bag that leaves the factory is safe and consistent.

Site Standard: The physical manufacturing environment is a critical component. BRC requires strict standards in factory hygiene, pest management, equipment maintenance, and personnel practices. The production facility must be clean and well-maintained to avoid contamination. It must also have proper ventilation, separation between production areas, and be designed to prevent contamination.

Traceability and Product Control: BRC-certified manufacturers must be able to trace every product. A clear chain of custody is required from the initial batch of raw materials to the final delivery of the product to the customer. This level of traceability allows for a quick and efficient response in the event of product recalls.

Process Control: BRC specifies requirements for specific production processes including printing, lamination, and bag-making. The BRC ensures that all inks, adhesives, and bags are safe for food and have the proper barrier properties that protect food from oxygen, moisture, and other external elements.

BRC certification isn’t a one-time achievement. It is an ongoing commitment to improvement. Regular, and often unannounced, audits ensure that the company is maintaining these high standards. This gives food brands and their consumers peace of mind.

Trends and the Future of the Global Food Packaging Industry

Food packaging is undergoing rapid change, fueled by consumer demand, technological innovation, and regulatory changes. The following are key trends:

The Rise of Flexible Packaging: Flexible packaging, which includes products such as gusset bags, stand-up pouches, and roll films, continues to dominate the marketplace. The advantages of flexible packaging include its lightweight nature, reduced material consumption, and lower shipping costs. Mordor Intelligence reported that flexible solutions held more than 56% of the market share in 2024 and were projected to grow with a strong CAGR.

Circular Economy and Sustainability: The demand for eco-friendly products is greater than ever. Brands want packaging that is recyclable, biodegradable, or made of post-consumer recycled materials (PCR). This trend forces manufacturers to develop new materials and processes that reduce environmental impact without compromising performance.

Advanced Barrier Technology: In order to extend shelf life, reduce waste, and support “clean label” claims, there is an increasing demand for high-barrier films that protect from oxygen, moisture, and UV light. Material lamination and coating innovations are increasingly important, and Yinshili, as a China Top Food Packaging Films Manufacturer, is at the forefront of this technology.

Customization and Digital Printing: Smaller brands, in particular, are moving from mass production to highly customized packaging that is produced in short runs. Digital printing offers greater flexibility in design, personal branding, and lower minimum order quantities. This allows companies to be more responsive and agile to market trends.

These trends show that the packaging market is more than just a simple container. It’s about a complete, high-quality, and sustainable solution.

Yinshili Packaging: Your Partner for Excellence

Yinshili Packaging’s six-year experience in manufacturing makes it uniquely qualified to meet the market demands. We are expanding internationally and can offer our partners an innovative product with proven expertise.

A Veteran in the Industry: We are not newcomers. We have 26 senior technicians, and more than 30 employees who each have over a decade’s experience. Our deep institutional knowledge and the success of more than 150 projects allow us to offer expert advice as well as handle custom orders. We have been in the business for six-years and our work speaks for itself.

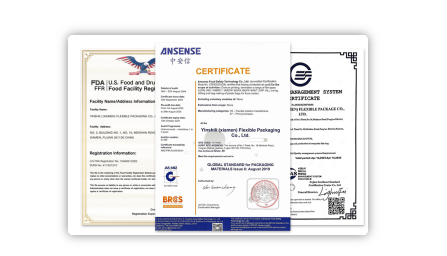

BRC Certified and Beyond: Our commitment to quality is demonstrated by our multiple certifications including BRC, FDA, and others. ISO9001 ensures all products are compliant with international standards. Our commitment to compliance is a part of our DNA.

Cutting-Edge Technology: We believe advanced technology will “inject new blood” into the packaging industry. We have 6 high-speed production lines that can produce 1 million bags per day. This ensures lightning-fast production and delivery. Our R&D department and advanced production methods set us apart from our competitors, providing superior performance in a wide range of applications. This includes our reputation as a China Leading Retort Food Pouches Exporter.

Tailored Solutions for Your Business: We can custom-design a packaging solution that will meet all of your needs, whether you require anti-static protection, leakage prevention, or UV protection. We provide OEM and ODM services that allow for custom-made designs, shapes, and performance characteristics to make your brand stand out.

A Diverse Portfolio of Products: We have a wide range of products that cater to many industries. We are experts in all types of rolls of film. These include BIB bags and three-side-seal pouches. Our gusset bag, in particular, is engineered to be durable and attractive, making it an ideal choice for many products.

We at Yinshili believe that the consumer deserves better packaging. Our confidence in our products is reflected by our impressive statistics: over 80 satisfied clients, 10+ different countries served, and 150+ successfully completed projects. We have the tradition and confidence to be a global brand.

Official Website: https://yslpackaging.com/

Yinshili Co., Ltd.

[email protected]

+86 18959490067

Factory 1, No. 16 Meishan Road, Tong’an District, Xiamen, Fujian, 361100, China

https://yslpackaging.com/

This article was originally published by IssueWire. Read the original article here.