(Isstories Editorial):- Wuhan, Hubei Nov 13, 2025 (Issuewire.com) – What enables a single grinding wheel manufacturer to seamlessly serve the diverse equipment requirements of global railway operators across continents? The answer lies in achieving universal compatibility across major rail grinding platforms–a feat that Fashan Railway has mastered through decades of engineering excellence. With perfect compatibility for Speno rail grinders, Loram grinding trains, Harsco equipment, Jinying Heavy Industry machines, China Railway Construction systems, Mecno grinders, Geismar equipment, and Robel machinery, Fashan demonstrates unparalleled worldwide compatibility that positions the company as the preferred partner for international railway maintenance operations.

This comprehensive compatibility achievement represents more than technical adaptation–it reflects deep understanding of diverse engineering standards, operational requirements, and performance specifications across the global railway maintenance industry. Fashan’s ability to deliver consistent quality across all major grinding platforms has established the company as an indispensable supplier for railway operators seeking unified solutions for their diverse equipment fleets.

Universal Engineering Excellence Across Grinding PlatformsSpeno International: Swiss Precision Standards

More on Isstories:

- Sparket Leverages Landmark Patent to Launch Sparket.AI

- Working Parents Are Choosing Business Ownership Over Jobs That Won’t Give Them Parental Leave

- Chesshir Stone – Rock Supply Expands Presence in Plano Following Acquisition of Contractors Stone Supply

- Burj2Burj 2026 Confirms Its Place as Dubai’s Iconic Half-Marathon

- Valentine’s Day Style Guide: How to Choose the Right Wig from Isee Hair

Speno International’s legendary grinding trains have set industry standards for precision rail maintenance since the company’s establishment. These sophisticated systems demand grinding wheels engineered to exacting Swiss precision standards while maintaining compatibility with Speno’s unique grinding head configurations and operational parameters.

Fashan’s grinding wheels for Speno equipment incorporate specialized formulations optimized for the company’s signature grinding patterns and pressure control systems. The wheels demonstrate exceptional performance in Speno’s traditional production grinding applications, where consistent material removal and surface finish quality are paramount for maintaining Speno’s reputation for excellence.

The compatibility extends beyond basic dimensional specifications to encompass performance characteristics that complement Speno’s grinding methodology. Fashan’s wheels maintain cutting efficiency throughout extended grinding campaigns while delivering the surface quality consistency that Speno operators depend upon for predictable results across diverse rail conditions.

Loram: American Innovation and Productivity Leadership

Loram’s rail grinders incorporate high power, flexible grinding modules and patented control systems to deliver industry-leading speed and proven productivity. Loram’s rail grinding product portfolio offers machine configurations from 4 to 120 stones, requiring grinding wheel suppliers with comprehensive compatibility across this extensive equipment range.

As the China Top Loram Grinding Wheel Supplier From China, Fashan has developed specialized solutions that optimize performance across Loram’s diverse equipment portfolio. From compact specialty grinders requiring six (6) in. (150 mm) grinding stones to production systems utilizing ten (10) in. (250 mm) grinding stones, Fashan’s wheels deliver consistent performance across all configurations.

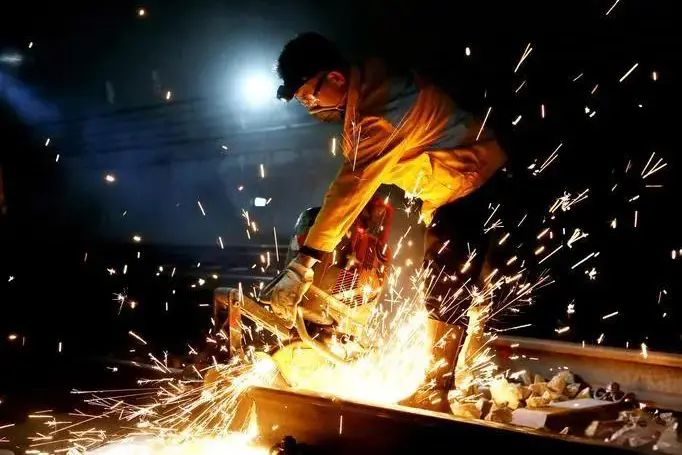

The compatibility with Loram’s high-speed production grinding operations demands wheels capable of maintaining cutting efficiency at speeds up to 20 km/h in open rail grinding applications. Fashan’s advanced manufacturing processes create wheels that withstand these demanding operational conditions while delivering the productivity that Loram customers expect.

Harsco Rail: Global Infrastructure Solutions

Harsco Rail’s comprehensive approach to railway maintenance encompasses diverse equipment platforms operating across multiple continents. This global presence requires grinding wheel suppliers with manufacturing capabilities and quality control systems that ensure consistent performance regardless of geographic location or operational environment.

Fashan’s role as the Best Harsco Grinding Wheel Factory reflects the company’s ability to meet Harsco’s demanding global standards while adapting to regional operational requirements. The wheels demonstrate reliable performance across Harsco’s diverse equipment portfolio, from specialized grinding systems to production-scale operations.

The compatibility achievement with Harsco equipment extends to comprehensive technical support that ensures optimal wheel selection and application optimization across different operational scenarios. This holistic approach provides Harsco operators with confidence in wheel performance while minimizing operational disruptions.

Asian Market Leadership and Technical ExpertiseChina Railway Construction Corporation: Domestic Excellence

China Railway Construction Corporation’s extensive network operations demand grinding wheels that meet the exacting standards of the world’s most advanced railway system. Fashan’s compatibility with China Railway equipment reflects deep understanding of domestic operational requirements and technical specifications.

The company’s wheels demonstrate exceptional performance across China Railway’s diverse rolling stock, from high-speed passenger networks requiring ultra-smooth surface finishes to heavy freight corridors demanding aggressive material removal capabilities. This versatility positions Fashan as an essential partner for China’s railway expansion and modernization initiatives.

Jinying Heavy Industry: Specialized Equipment Solutions

Jinying Heavy Industry’s specialized grinding equipment requires suppliers with comprehensive technical expertise and manufacturing flexibility. Fashan’s compatibility with Jinying systems demonstrates the company’s ability to adapt to unique operational requirements while maintaining consistent quality standards.

The collaboration with Jinying Heavy Industry showcases Fashan’s commitment to supporting domestic equipment manufacturers through specialized grinding wheel solutions that optimize performance while ensuring operational reliability across diverse maintenance scenarios.

Mecno and European Integration Standards

The Top Mecno Grinding Wheel Exporter From China designation reflects Fashan’s successful penetration of European markets where technical standards and performance expectations represent the pinnacle of industry requirements. Mecno’s grinding systems demand wheels that meet stringent European quality standards while delivering consistent performance across diverse operational environments.

Fashan’s wheels for Mecno equipment incorporate advanced materials and manufacturing processes that ensure compliance with European safety standards while maintaining the cutting efficiency and durability that Mecno operators demand. This achievement demonstrates Fashan’s ability to compete successfully in the world’s most demanding markets.

Comprehensive Manufacturing Excellence and Quality AssuranceAdvanced Production Capabilities

Since its establishment in 1999 as China’s first rail grinding abrasive manufacturer, Fashan has continuously invested in advanced manufacturing technologies that enable universal compatibility across global equipment platforms. The company’s sophisticated hot-pressing equipment and precision quality control systems ensure consistent product characteristics regardless of target equipment specifications.

Wuhan Huatie Ruijie Rail Transit Technology Co., Ltd. has maintained focused dedication to continuous research and development for over 20 years, with specialized expertise in adapting grinding wheel formulations to diverse equipment requirements. This sustained investment in innovation enables the company to quickly respond to new compatibility challenges while maintaining proven reliability across existing platforms.

Precision Engineering and Dimensional Control

Universal compatibility demands exceptional precision in dimensional control and performance characteristics. Fashan’s advanced testing equipment verifies critical specifications including wheel diameter, thickness, aperture dimensions, and balance characteristics to ensure perfect fit across all supported equipment platforms.

The company’s “Lean craftsmanship ensures railway safety” philosophy translates into comprehensive quality assurance measures that verify compatibility requirements before product delivery. This rigorous approach prevents operational disruptions while ensuring optimal performance across diverse equipment configurations.

Global Operational Success and Market ValidationProven Track Record Across International Markets

Fashan’s extensive operational experience spanning 2 million kilometers of railway maintenance operations provides comprehensive validation of universal compatibility achievements. This global experience encompasses diverse operational environments, from arctic conditions in northern railways to tropical applications in equatorial regions.

The maintenance of over 10,000 turnout sets demonstrates Fashan’s expertise in complex grinding applications where precision and reliability are paramount. Turnout maintenance represents one of the most demanding compatibility challenges due to complex geometries and varied equipment requirements across different manufacturers.

Technical Support and Application Optimization

Fashan’s universal compatibility extends beyond product manufacturing to encompass comprehensive technical support that helps operators optimize grinding wheel selection and application parameters across different equipment platforms. This holistic approach ensures maximum value from grinding wheel investments while minimizing operational complexities.

The company’s global technical support network provides local expertise that understands regional operational requirements and equipment configurations. This localized support capability enables rapid response to technical challenges while ensuring consistent performance standards across all supported platforms.

Innovation Leadership and Future Development

The achievement of universal compatibility across major grinding platforms positions Fashan to capitalize on emerging trends in railway maintenance automation and digitalization. Smart grinding systems incorporating real-time performance monitoring and adaptive control capabilities will require grinding wheels with enhanced compatibility features and performance characteristics.

Fashan’s ongoing research and development initiatives focus on expanding compatibility capabilities while incorporating advanced materials and manufacturing processes that address evolving industry requirements. The company’s commitment to innovation ensures continued leadership in universal compatibility achievement as the railway maintenance industry continues evolving.

The integration of predictive maintenance technologies and artificial intelligence into railway maintenance operations creates opportunities for grinding wheel optimization that extends beyond traditional compatibility requirements. Fashan’s technical expertise positions the company to develop next-generation solutions that capitalize on these technological advances while maintaining proven compatibility with existing equipment platforms.

For comprehensive information about worldwide compatibility solutions and technical specifications across all major grinding platforms, visit https://www.fashanrailway.com/

This article was originally published by IssueWire. Read the original article here.