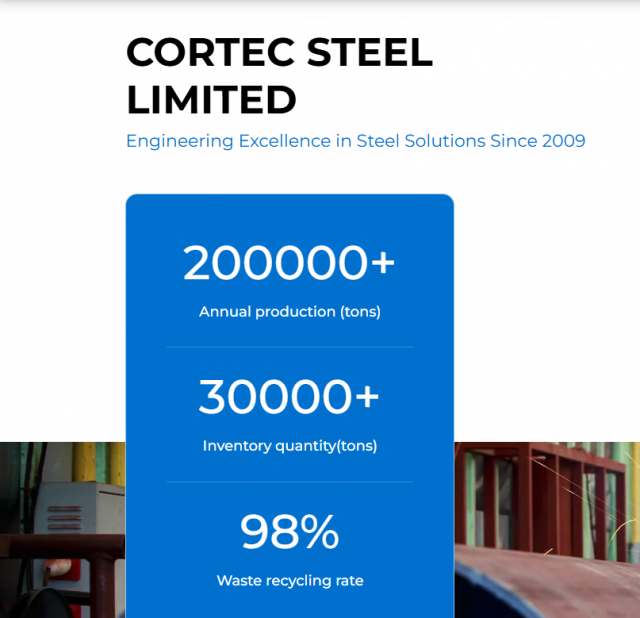

(Isstories Editorial):- Tianjin, China Nov 9, 2025 (Issuewire.com) – China Top Seamless Steel Pipe Manufacturer CORTEC STEEL stands as a global exemplar of engineering precision, delivering integrated steel pipe solutions that form the backbone of the world’s most demanding infrastructure, energy, and industrial projects. In the high-stakes sectors of oil, gas, power generation, and construction, where the stakes are measured in millions of dollars and human safety, the integrity of a pipeline is non-negotiable. CORTEC STEEL has carved out a pioneering role in the high-pressure steel pipe manufacturing industry by consistently exceeding these stringent requirements. Specializing in a full lifecycle approach–covering manufacturing, extensive stocking, and global distribution–the company ensures not only superior product quality but also rapid logistical support. This foundation is buttressed by an exhaustive roster of international certifications, including ISO 9001, ISO 45001, API 5L, API 5CT, and EN 10219, establishing CORTEC STEEL as a trusted, high-performance partner in the global steel supply chain.

The Foundation of Trust: CORTEC STEEL‘s Core Competitive EdgeMulti-Faceted Certification Ecosystem

The most immediate and powerful differentiator for CORTEC STEEL is its integrated certification and quality assurance system. In the steel pipe industry, certifications are not mere labels; they are critical barriers to entry and direct indicators of product reliability and compliance. CORTEC STEEL’s extensive portfolio of accreditations attests to its adherence to global best practices across quality, safety, and specialized industry applications.

More on Isstories:

- Seamless Superiority: How CORTEC STEEL Pioneers China’s High-Pressure Steel Pipe Manufacturing

- Imagen Network Collaborates with Grok to Advance Real-Time Creator Personalization

- Atua AI Strengthens Developer Efficiency with Real-Time Workflow Automation

- Green Vehicle Disposal and EZ Suite Announce Strategic Partnership

- Engineered Softness: Yituo Sets the Global Benchmark for Premium Chenille Fabrics

Integrated Solution Model: Manufacturing, Stocking, and Distribution

CORTEC STEEL excels not just as a manufacturer, but as an integrated solution provider. This vertical capability is crucial in mitigating the volatile nature of global commodities and project timelines:

Manufacturing Excellence: Focused on seamless steel pipe production, the company controls the metallurgical composition and mechanical properties precisely, ensuring the finished pipe meets the exact tensile strength, yield strength, and dimensional tolerances required for high-pressure applications.

Strategic Stocking: By maintaining substantial inventory, CORTEC STEEL can offer rapid turnaround times, a major competitive advantage in projects facing tight deadlines or unexpected supply chain disruptions. This large stockholding covers a range of critical grades (e.g., API 5L X65, X70, API 5CT L80, P110), allowing for emergency supply or swift deployment for fast-track projects.

Global Distribution Network: An established distribution system ensures efficient logistics from China to project sites worldwide, cutting down shipping complexity and associated costs for international clients.

Product Application and Client-Centric SuccessCore Product Portfolio and High-Stakes Applications

CORTEC STEEL’s core focus on seamless steel pipes places its products at the heart of mission-critical global industries. Seamless pipe, manufactured without any weld, is inherently stronger and more reliable under high-stress conditions than its welded counterpart, making it the material of choice for demanding uses.

Oil and Gas (O&G) Transportation and Extraction:

API 5L Line Pipe: Used in mainline pipeline construction for the long-distance transmission of crude oil, natural gas, and refined products under extremely high pressures and temperatures.

API 5CT Casing and Tubing: Essential for the structural integrity of oil and gas wells (downhole). Casing lines the wellbore, preventing collapse and fluid contamination, while tubing transports the extracted product to the surface. High-grade materials (like P110) are mandatory for deep, challenging well environments.

Power Generation:

Seamless pipes are used in high-pressure boilers, heat exchangers, and superheaters within thermal and nuclear power plants, where steam and water are handled at extreme temperatures and pressures.

Industrial Processing and Petrochemicals:

Used in chemical reactors, refinery piping, and high-pressure hydraulic systems where pipe failure is catastrophic. The uniform structure of seamless pipe offers superior corrosion resistance and predictability.

Specialized Infrastructure:

Used in structural piling, deep foundations, and certain bridge components where immense load-bearing capacity and structural integrity are paramount.

Illustrative Client Partnership Scenarios (Conceptual)

While specific customer contracts are confidential, CORTEC STEEL’s capabilities suggest the following types of successful collaborations:

Scenario 1: Major Cross-Continental Pipeline Project: A consortium undertaking a large-scale natural gas pipeline project (requiring thousands of kilometers of API 5L X70 pipe) selects CORTEC STEEL. The primary drivers are the guarantee of API 5L quality certification (PSL2 grade for enhanced toughness) and the ability to maintain a just-in-time delivery schedule for massive volumes, minimizing project delays and regulatory risks.

Scenario 2: Deep-Water Offshore Drilling: An international exploration company requires specialized, high-yield strength casing (e.g., API 5CT P110 grade) for a challenging deep-water well. CORTEC STEEL’s advanced manufacturing and heat treatment processes ensure the tubular goods have the necessary material integrity and tight dimensional control to withstand extreme hydrostatic pressure and corrosive elements, preventing non-productive time (NPT).

Scenario 3: Rapid Replacement Supply: A large-scale chemical plant experiences unexpected pipe failure in a high-temperature processing unit. Utilizing CORTEC STEEL’s extensive 30,000-ton stockpile, the plant is able to source the highly specialized, thick-walled seamless pipe (e.g., ASTM/ASME standard) required for replacement within days, drastically reducing costly operational downtime.

Industry Outlook: Trends Shaping the Seamless Pipe MarketMarket Dynamics: Growth Drivers and Regional Shifts

The global seamless steel pipe market is projected for robust growth, driven by fundamental energy and infrastructure needs. Market analysts forecast a steady Compound Annual Growth Rate (CAGR), pushing the market valuation higher over the next decade.

Oil & Gas Resilience and Deep Drilling: Despite the transition to renewable energy, the oil and gas sector remains the largest consumer of seamless pipes. Growth is driven by the complexity of modern extraction–specifically deep-water, horizontal, and unconventional drilling, which demand pipes (API 5CT and API 5L) with progressively higher strength, increased resistance to corrosion (HS, CO), and superior fracture toughness.

Infrastructure Development in Asia-Pacific: The Asia-Pacific region, including China, is the largest and fastest-growing seamless pipe market globally. Massive infrastructure projects, urbanization, and the expansion of domestic energy and chemical networks fuel sustained high demand for construction and process piping.

Substitution of Welded Pipe: In high-stakes applications, there is an increasing regulatory and safety-driven trend to substitute welded pipe with seamless pie, especially for medium-to-high pressure transmission, further expanding CORTEC STEEL’s core market opportunity.

Navigating Innovation and Sustainability Trends

The future of steel pipe manufacturing is dictated by technological advancement and environmental compliance, trends that CORTEC STEEL is well-positioned to leverage:

Smart Materials and Traceability: The industry is moving towards smart pipes that can integrate sensors for real-time monitoring of corrosion and stress. Manufacturers must develop pipes with superior material consistency and provide digital traceability (via CNAS and ISO certified documentation) of every pipe section, ensuring absolute transparency from melt shop to installation.

Low-Carbon and Sustainable Manufacturing: Global pressure to reduce carbon footprints (Scope 1 and 2 emissions) is increasing. Future competitive advantage will go to manufacturers who invest in energy-efficient production processes and can demonstrate lower-carbon content steel, appealing to major energy companies with net-zero commitments.

Advanced Metallurgy for Extreme Conditions: Ongoing R&D is required to develop new steel grades (beyond X80/X100) that offer improved strength-to-weight ratios and enhanced resilience to extreme temperatures and corrosive sour service environments without compromising cost-effectiveness.

By combining its stringent quality control (ISO, API) with an agile, integrated supply chain model, CORTEC STEEL is strategically positioned to meet the global market’s escalating need for high-integrity, high-pressure seamless steel pipes. As the world continues to rely on robust energy and infrastructure solutions, CORTEC STEEL’s commitment to Seamless Superiority ensures its continuing role as a leader in China’s manufacturing sector and a trusted supplier worldwide.

To learn more about CORTEC STEEL’s integrated seamless steel pipe solutions and certifications, please visit their official website: https://www.cortecsteel.com/

Tel+ 86 137 5258 0888

Address: 9c Northern Finance Building, Hexi District, Tianjin,China 300021

This article was originally published by IssueWire. Read the original article here.