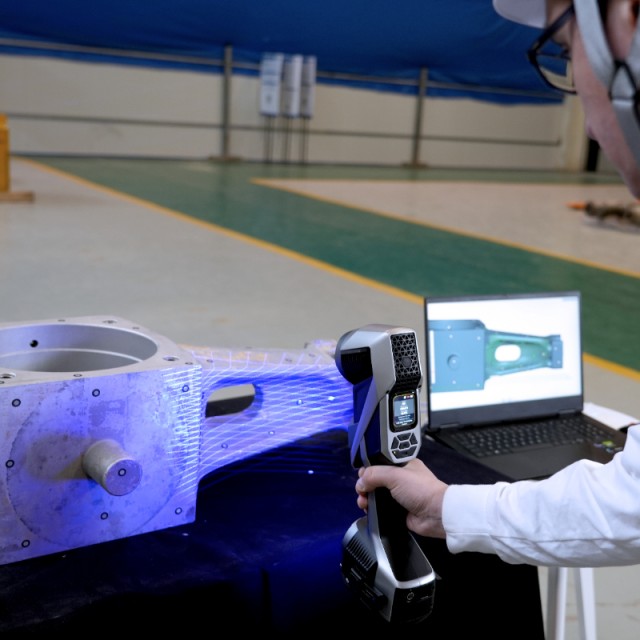

(Isstories Editorial):- Hangzhou, Zhejiang Sheng Nov 10, 2025 (Issuewire.com) – In a world where precision and speed in manufacturing and product lifecycle management determine competitive advantage, SCANOLOGY proudly announces its latest suite of solutions designed for 3D scanning for reverse engineering parts, offering seamless integration of high-precision hardware and advanced software tools. Our systems capture detailed geometry of components that may lack existing CAD data, enabling engineers to rapidly recreate, analyze and optimize parts across the entire development and manufacturing chain. By combining high-precision 3D scanners, mobile and portable devices, and workflow-oriented software platforms, SCANOLOGY delivers reverse-engineering workflows with unprecedented accuracy, speed and flexibility.

Industry Outlook and Market Trends

The global industrial metrology and 3D scanning markets are experiencing robust growth, driven by demands for complex geometry verification, quality inspection, virtual twin development and digital manufacturing transformation. The global 3D metrology market was estimated at USD 10.35 billion in 2023, and is projected to reach nearly USD 19.51 billion by 2030, at a compound annual growth rate of approximately 9.2 %. Grand View Research

Meanwhile, the broader 3D scanning market itself is poised to grow from approximately USD 5.1 billion in 2024 to an estimated USD 14.2 billion by 2034, driven by applications in automotive, aerospace and advanced manufacturing. Global Market Insights Inc.+1

These trends reflect critical shifts: manufacturers are increasingly integrating metrology-grade scanning into production lines, quality-control operations are becoming more digitally oriented, and reverse engineering workflows–where legacy or modified parts are scanned, reconstructed and re-manufactured–are emerging as key enablers of innovation and sustainability. In industries such as aerospace, automotive and heavy equipment, parts complexity continues to rise, materials are more challenging, and tolerance demands tighter: all of which reinforce the need for integrated hardware/software metrology systems. Moreover, the trend toward digital twins, Industry 4.0 smart factories and additive manufacturing means that companies now require measurement systems that not only capture geometry but also feed actionable data into upstream and downstream processes.

More on Isstories:

- Top Rated Handheld 3D Scanner for Industrial Maintenance Applications

- Best Reverse Engineering and Metrology Software Integration Solutions in the World

- The Future Is Bright: Leading Sign Company in Louisville, KY, Helps Local Businesses Shine

- YES Containers Expands Fast, Affordable Shipping Container Delivery Across the United States

- PGA Demo Day 2026: The Outdoor Simulator Playground Every Golfer Needs to See

Our Certification Commitment

At SCANOLOGY, we believe that world-class solutions are underpinned by trusted processes, quality systems and information security. We are pleased to confirm that we hold the following certifications, which reflect our commitment to operational integrity and customer confidence:

- ISO 17025:2017 – General requirements for the competence of testing and calibration laboratories

- ISO 9001:2015 – Quality management systems – requirements

- ISO 14001:2015 – Environmental management systems

- ISO 45001:2018 – Occupational health and safety management system

- ISO/IEC 27001:2022 – Information security management systems

- ISO/IEC 27701:2019 – Privacy information management within the context of

These certifications are integrated into our company culture and practices–from device manufacturing, system calibration, software development, and data security to on-site service and support.

Core Strengths, Product Lines and Application Scenarios

SCANOLOGY stands out globally due to our fusion of hardware and software capabilities. On the hardware side, we design and manufacture industrial high-precision 3D scanners and systems (such as fixed multi-camera optical rigs and automated turntable/robotic scanning stations) alongside cost-effective portable and professional scanners (handheld 3D scanners, optical 3D scanners, and professional colour 3D scanners). On the software side, we deliver integrated solutions that streamline data capture, mesh processing, CAD/CAE export, inspection feedback loops and reverse engineering workflows.

Our product lines are tailored for two major segments:

Industrial-grade metrology solutions: Targeting aerospace, automotive, heavy industry, power-generation and engineering sectors. These systems handle large-scale parts, tight tolerances, high throughput inspection and automated production-line integration.

Professional and cost-effective 3D scanning solutions (under the brand 3DeVOK): Addressing 3D printing, art & museum digitisation, medical & health, public security & forensics, and virtual-world/entertainment applications.

In reverse engineering scenarios, a legacy cast component or wear-out sheet-metal part can be captured using our scanner, processed in software to generate a CAD-ready model, compared to original drawings, iterated for improvement, and transferred for production. In inspection applications, automotive body-in-white, aerospace structural assemblies or heavy-machinery parts can be scanned and compared to nominal CAD, with deviations reported and corrective actions triggered.

Our clients include leading OEMs and tier-1 suppliers in aerospace and automotive, heavy-machinery manufacturers and major cultural-heritage institutions. For example, a global aerospace provider utilised our automated 3D system to reverse-engineer an aging turbine-component geometry, enabling replacement manufacturing with no original drawings. Another automotive supplier integrated our portable scanner into their line for rapid inspection of BIW (body in white) weld-fixtures, reducing inspection time by over 40 %.

Through these application scenarios, we demonstrate how SCANOLOGY empowers customers to transition from manual, time-consuming measurement practices to fully integrated, intelligent metrology workflows–supporting faster product development cycles, higher quality assurance, reduced scrap and more efficient maintenance/repair operations.

Why SCANOLOGY?

- End-to-end solution capability: From scanner hardware and automated scanning stations to software for reverse engineering, inspection and metrology.

- High precision and portability: Our industrial scanners deliver micron-level accuracy, while our portable units bring flexibility to field or shop-floor use.

- Industry-specific specialization: We understand the requirements of aerospace, automotive and heavy industry–and we deliver accordingly.

- Global service and support: With a worldwide presence, customers receive local calibration, training and maintenance services aligned with certified standards.

- Innovation-driven: We continuously invest in R&D to stay ahead of the scanning, automation and data-analysis technology curve.

- Trusted compliance: Our multiple international certifications underline our commitment to quality, safety, environment, information security and privacy compliance.

In today’s dynamic manufacturing environment, companies must leverage advanced technologies–not merely hardware or software in isolation–but integrated systems that deliver actionable insights, support agile production and ensure measurement integrity. SCANOLOGY is uniquely positioned to deliver such integrated solutions for 3D scanning for reverse engineering parts and comprehensive metrology workflows.

For more about our offerings, information, client success stories and how your organization can benefit, please visit our website: https://www.3d-scantech.com/

This article was originally published by IssueWire. Read the original article here.