(Isstories Editorial):- Xian, Shaanxi Nov 8, 2025 (Issuewire.com) – The global wine and beverage industry is increasingly reliant on high-efficiency, sterile, and sustainable packaging solutions. Among these, the Bag-in-Box (BIB) format is paramount for its ability to extend product shelf life and minimize environmental impact. Xi’an Shibo Fluid Technology Co., Ltd. (SBFT), a pioneer in fluid packaging machinery, is proud to announce its participation in the upcoming PROPAK exhibition, where it will feature its groundbreaking fully automatic filling systems. SBFT is recognized as a premier China Fully Automatic Bag In Box Wine Filler Supplier. These sophisticated machines are engineered with high precision to handle the delicate filling process, drastically reducing oxygen pickup and ensuring aseptic conditions–factors critical for maintaining the flavor, aroma, and longevity of wine and other sensitive beverages. By offering integrated automation, SBFT’s innovative fillers are helping wineries and liquid producers worldwide achieve unprecedented levels of productivity and quality control.

I. Industry Trends and Market Outlook: The Surge in Aseptic and Automated BIB Packaging

The current trajectory of the global packaging industry is defined by twin drivers: the demand for higher automation and the imperative for sustainability. The Bag-in-Box sector is perfectly positioned to capitalize on these trends, providing significant growth opportunities for specialized equipment manufacturers like SBFT.

More on Isstories:

- Meet SBFT at PROPAK: Showcasing the Latest Fully Automatic Bag in Box Wine Filling Innovation

- Writer Antonia Loukousia Reflects on America’s Loneliness Epidemic: “We Have Forgotten How to Belong”

- CEIC 2025: A deep integration of technology, scenario and ecology

- SBFT Strengthens Its Global Reach with Innovative Aseptic BID Tomato Paste Filling Systems

- Why Choose a High-Quality Bag In Box Filler Filling Machine Manufacturer Like SBFT

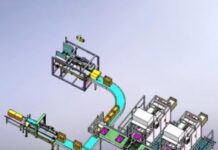

- The Automation Imperative and Productivity Gains:The transition from manual or semi-automatic filling to fully automated systems is critical for large-scale operations. Automation, a field where SBFT has pioneered with its BIB500 AUTO, mitigates human error, ensures highly accurate dosing, and significantly increases throughput–factors essential for managing high-volume production with thin profit margins. This efficiency allows producers to meet surging global demand, particularly in the bulk wine, juice concentrate, and industrial liquid markets.

- Sustainability as a Market Differentiator:The BIB format’s ecological advantage is a major market catalyst. Using less packaging material and being lighter than traditional glass, BIB reduces carbon emissions associated with production and transportation. As global corporations adopt ambitious sustainability goals, the reliable supply of certified, energy-efficient filling equipment is non-negotiable. SBFT’s commitment to “European quality machine” design focuses on precision and durability, which minimizes material waste during the filling process, further enhancing the environmental profile of the packaged product.

- Expansion of Aseptic Applications:Beyond wine, the market for aseptic BIB filling is exploding in liquid food sectors. Products like liquid egg, dairy alternatives, and high-value fruit concentrates require absolute sterility to ensure non-refrigerated distribution and extended shelf life. SBFT’s specialized aseptic lines, such as the ASP100AUTOand ASP300 tonnage aseptic filling machine, address this need directly, unlocking new export markets for producers. The ability to efficiently handle vast volume ranges–from consumer-friendly 2L and 3L bags up to industrial 1000L totes–positions BIB filling at the center of the modern liquid supply chain.

- Digital Integration and Quality Control:The future of filling technology involves smarter machines capable of real-time monitoring and predictive maintenance. This trend, which demands machinery certified to stringent international standards, ensures operational continuity and superior product quality, reinforcing the importance of suppliers with proven track records and robust certification portfolios.

II. Global Platform and Quality Assurance: SBFT’s Presence and Certifications

SBFT’s reputation for delivering “European quality machine” from its base in Xi’an, China, is underpinned by its rigorous adherence to international quality standards and its strategic engagement with global packaging and processing communities.

- Core Certifications for International Trust:Ensuring product safety and compliance is paramount for operating across global markets. SBFT holds key certifications that attest to the quality and safety of its filling systems:

CE Certificate (Achieved in 2013): This critical mark demonstrates that SBFT’s machinery conforms with the health, safety, and environmental protection standards of the European Economic Area (EEA), which is vital for sales and operation in Europe and other markets that recognize the CE standard.

FDA Compliance Commitment: For a leading supplier of liquid food equipment, especially those handling milk, juices, and liquid eggs, adherence to the FDA (U.S. Food and Drug Administration) standards is essential. This compliance ensures that the materials and sanitary design of the equipment meet the stringent requirements necessary for processing and packaging food destined for the North American market.

- The PROPAK Showcase and Global Exhibition Strategy:Participation in leading trade shows is central to SBFT’s strategy of engaging directly with current and potential clients across diverse geographical markets. The PROPAKexhibition serves as a vital platform for the company to highlight its innovations, particularly in the fully automatic wine filling segment, allowing attendees to witness the high precision and reliability of the machines firsthand.

In addition to PROPAK, SBFT strategically exhibits at:

CIBUS: Engaging the European food processing sector, specifically showcasing aseptic filling for dairy and food concentrates.

GULFOOD Machinery: Targeting the rapidly expanding Middle Eastern and African markets, emphasizing large-scale and versatile filling solutions for various beverages and bulk liquids.

At these events, SBFT presents its full spectrum of solutions, including the groundbreaking BIB500 AUTO (the first fully automatic non-aseptic filler produced by a Chinese company) and the high-speed aseptic line ASP100AUTO, showcasing their suitability for containers ranging from small consumer bags to industrial 1000L totes. This global presence confirms the company’s aim to be a truly global provider of packaging excellence.

III. Innovation, Performance, and Customer Value: The SBFT Difference

SBFT’s longevity and market position as the “biggest and most professional bag-in-box filling machine manufactured in China” are built upon a powerful combination of focused expertise, technical innovation, and a clear, customer-centric philosophy.

- Core Philosophy and Experience:Since its founding in 2006, SBFT has amassed 15 years of R&D and manufacturing experience, leading to institutional knowledge that few competitors possess. The director’s mantra–“we just need to do every detail well and we just only focus on what we are doing now”–translates directly into equipment characterized by superior build quality and reliability. This focus ensures the lowest machine maintenanceand the best machine working performance.

- Technical Pioneering and Product Versatility:SBFT’s innovation track record includes being the first company in China to produce a fully automatic non-aseptic BIB machine (the BIB500 AUTO). This pioneering spirit extends to its wide product line, which effectively addresses virtually every liquid packaging need:

Aseptic Excellence: Filling lines like the ASP100AUTO provide microbial security crucial for perishable products such as liquid egg, milk, and coconut milk, extending market reach without reliance on cold chains.

Non-Aseptic Precision: High-speed fillers, including those targeting the wine sector, ensure accurate volume control and minimal oxidation, crucial for preserving wine quality.

Comprehensive Scale: The ability to handle small format bags (2L, 3L, 5L) alongside massive industrial 1000L bags using specialized equipment like the ASP300 ensures SBFT is a one-stop solution for producers of all sizes.

- Application Success and Value Proposition:SBFT’s machines are universally applicable to a wide spectrum of liquids, including: water, wine, fruit juices, concentrates, liquid egg, edible oil, coffee, liquid food products, and various non-food chemicals/fertilizers.The company’s persistent pursuit is to provide the competitive machine price without compromising performance. For customers, the primary benefit is not just the equipment itself, but the commitment to ensuring the SBFT bag-in-box filling machine is the most suitable equipment for customer products, maximizing their operational success and return on investment globally. This dedication to offering the best filling solutions is why SBFT has achieved market leadership.

Conclusion

SBFT invites all industry professionals attending PROPAK to visit their booth and witness the future of liquid packaging. By combining high-precision, automatic systems with rigorous quality certifications and a commitment to customer success, SBFT continues to define the standard for Bag-in-Box filling technology. The debut of their latest innovations at PROPAK solidifies SBFT’s role as an indispensable partner for wineries and liquid manufacturers worldwide seeking to maximize efficiency and embrace sustainable packaging solutions.

Website: https://www.bibfiller.com/

This article was originally published by IssueWire. Read the original article here.