(Isstories Editorial):- Jiangyin, Jiangsu Sheng Oct 29, 2025 (Issuewire.com) – As industries evolve and production processes become increasingly automated, the need for high-quality, durable, and efficient conveyor systems has grown exponentially. Conveyor belts play a crucial role in ensuring smooth and continuous operations in sectors like manufacturing, logistics, food processing, and e-commerce. Jiangyin Lonovae Technology Co., Ltd., founded in 2015 and based in Jiangyin City, China, is emerging as a Future Leading PP Conveyor Belts Supplier, offering cutting-edge Polypropylene (PP) conveyor belts that set new standards for performance, durability, and sustainability. The company has made a name for itself by providing premium PP conveyor belts that combine the benefits of lightweight design, high resistance to wear, and exceptional strength, making them ideal for various industrial applications.

Lonovae, a plastic manufacturing specialist, initially focused on providing returnable transport packaging solutions like collapsible pallet pack containers, collapsible bulk containers, and PP honeycomb panels. These products have helped numerous businesses in diverse industries optimize their logistics and supply chain processes while reducing environmental impact. Building on this expertise, Lonovae has now expanded its product offerings to include high-performance PP conveyor belts, marking a significant step towards becoming a future leader in the conveyor belt industry. These conveyor belts are made from pure PP material, known for its remarkable resistance to chemicals, heat, and wear, and provide companies with long-lasting, low-maintenance solutions for their production and material handling needs.

The Growing Demand for Advanced Conveyor Belt Solutions

More on Isstories:

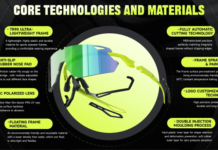

- Floating Sunglasses: Innovation and Quality in China’s Leading Manufacturers with Global Certifications

- Liansheng Assembly to Showcase Integrated House with Full Assembly Service at SCO 2025 Expo

- Openex: An International Metal Fabrication Pioneer

- ISO vs. CE Certification: How Openex Prioritizes Quality in Metal Fabrication

- How to Customize Your Own Logo on Sports Sunglasses — A Complete Guide for Brands

The global demand for conveyor systems is increasing as industries embrace automation and more efficient material handling systems. Conveyor belts, once seen as a simple tool for transporting goods, have evolved into highly sophisticated systems that integrate with other machinery, sensors, and control systems to create streamlined, automated production lines. Industries across the board are embracing these technological advancements to increase throughput, reduce human error, and lower operational costs.

A key factor driving the demand for advanced conveyor belts is the need for higher operational efficiency. In manufacturing plants, distribution centers, and food processing units, conveyor systems enable the swift and smooth movement of materials, components, and finished goods. However, not all conveyor belts are created equal. Traditional materials such as rubber and fabric have limitations when it comes to durability, wear resistance, and the ability to perform under extreme conditions. This is where polypropylene (PP) conveyor belts come into play. Known for their lightweight construction, chemical resistance, and high tensile strength, PP conveyor belts offer a significant advantage over conventional materials.

In addition to offering superior mechanical properties, PP conveyor belts are also a sustainable choice. With growing awareness about the environmental impact of industrial operations, companies are increasingly seeking materials that are recyclable, non-toxic, and energy-efficient. Polypropylene, being a fully recyclable plastic, fits the bill perfectly. As such, the shift towards PP conveyor belts is part of a broader trend in industries adopting greener and more sustainable manufacturing processes.

Furthermore, as global supply chains become more complex and industries move towards increased automation, the role of conveyor belts in maintaining smooth operations has never been more critical. Industries such as e-commerce, automotive, and logistics are relying on advanced conveyor systems to meet the growing demands of fast-paced, high-volume production and distribution. With the trend towards automation and sustainability showing no signs of slowing down, companies like Lonovae are poised to play a central role in meeting these evolving industry needs with their high-performance PP conveyor belts.

Lonovae’s Core Advantages: Innovation, Quality, and Versatility

Jiangyin Lonovae Technology Co., Ltd. stands out as a Future Leading PP Conveyor Belts Supplier due to its relentless commitment to quality, innovation, and sustainability. The company’s extensive experience in plastic manufacturing has provided them with the expertise necessary to develop high-quality PP conveyor belts that meet the stringent requirements of modern industries.

One of the primary advantages of Lonovae’s PP conveyor belts is their exceptional durability. Made from pure polypropylene, these belts are resistant to a variety of harsh environmental conditions, including extreme temperatures, chemicals, moisture, and abrasion. Whether used in the food processing industry, automotive manufacturing, or logistics, Lonovae’s conveyor belts are engineered to withstand the toughest challenges and maintain consistent performance over time. The lightweight nature of PP also reduces energy consumption, making Lonovae’s conveyor belts not only a durable option but also an energy-efficient one.

Lonovae’s focus on environmental sustainability is another key differentiator. In line with global trends toward eco-friendly solutions, the company uses recyclable PP material for its conveyor belts, contributing to the reduction of industrial waste and supporting a circular economy. Furthermore, the belts’ long lifespan reduces the frequency of replacements, contributing to lower waste and reduced environmental impact.

Beyond durability and sustainability, Lonovae’s PP conveyor belts are highly versatile and can be customized to suit a wide range of industrial applications. The company offers various designs, sizes, and configurations, ensuring that their products can meet the specific needs of their clients. Whether it’s for transporting heavy-duty products in a warehouse or for delicate items in a food processing plant, Lonovae’s conveyor belts are adaptable and can be tailored to meet the unique challenges of each industry.

Key Applications and Industry Clients

Lonovae’s PP conveyor belts are designed to excel in a variety of industries, offering tailored solutions that meet the unique needs of each sector. Some of the key applications include:

Food Processing Industry: The PP conveyor belts are ideal for the food processing industry due to their high resistance to oils, fats, and food acids. These belts ensure the safe and hygienic transport of food products through various stages of processing, minimizing contamination risks and ensuring efficiency.

Logistics and Warehousing: Lonovae’s conveyor belts are extensively used in logistics and warehouse operations, where high-speed transportation of goods is essential. The belts’ low friction properties and resistance to wear make them suitable for heavy-duty applications, ensuring that goods are moved smoothly and efficiently from one point to another.

Automotive and Manufacturing: In automotive and manufacturing plants, where heavy components are often transported, Lonovae’s PP conveyor belts provide a strong, reliable solution. Their ability to handle heavy loads while maintaining consistent performance over time makes them an essential component in automated production lines.

E-commerce: With the rapid growth of e-commerce, efficient material handling systems have become more crucial than ever. Lonovae’s PP conveyor belts are widely used in e-commerce fulfillment centers, where quick and accurate order picking and packaging are essential for meeting customer demands.

Pharmaceuticals and Electronics: The electronics and pharmaceutical industries rely on high-precision operations. Lonovae’s conveyor belts provide the clean and consistent transport needed for sensitive products, ensuring that the highest standards of hygiene and reliability are maintained.

Lonovae’s commitment to customer satisfaction has led to successful collaborations with major companies in diverse industries. The company has built a strong reputation for delivering high-quality, reliable, and cost-effective conveyor solutions, earning the trust of both small businesses and large multinational corporations.

Conclusion

Jiangyin Lonovae Technology Co., Ltd. is rapidly positioning itself as a Future Leading PP Conveyor Belts Supplier, offering high-performance polypropylene conveyor belts that provide superior durability, sustainability, and versatility. As industries continue to demand more efficient and eco-friendly solutions for their production and logistics needs, Lonovae’s commitment to innovation and quality ensures that it will remain at the forefront of this growing market. Whether in food processing, logistics, automotive manufacturing, or e-commerce, Lonovae’s PP conveyor belts are designed to enhance operational efficiency and contribute to a sustainable future.

For more information about Lonovae’s products and services, visit their official website: https://www.lonovae.com/.

Jiangyin Lonovae Tenology Co., Ltd.,

[email protected]

8618661010305

https://www.lonovae.com/

This article was originally published by IssueWire. Read the original article here.