Ushering in a AI New Era of Optical Automation for CAPA Camera

(Isstories Editorial):- Ambler, Pennsylvania Oct 8, 2025 (Issuewire.com) – Hushan Autoparts Inc., a leading manufacturer of automotive fasteners, optical components, and automation systems, today announced the deployment of its latest-generation AA (Active Alignment) Automatic Assembly and Calibration System on its automotive lens production lines. This investment marks a major leap in Hushan’s capabilities in optical precision manufacturing and intelligent automation, strengthening its competitive edge in global automotive optics.

More on Isstories:

- Level Up Garage Door Pros Delivers Expert Garage Door Services in League City, TX

- Tips for Wedding Photos: How Lily – Lime Helps Couples Capture Their Big Day Beautifully

- Local Cleaning Services Sets the Standard for Carpet – Upholstery Cleaning in Los Angeles, CA

- 2Quick Garage Doors Woodlands Provides Trusted Garage Door Services in The Woodlands, TX

- From Babble to Reading Carrie Peoples’ Reading System Empowers Children to Learn Through Simplicity and Play

* A Major Step Forward in Automated Manufacturing

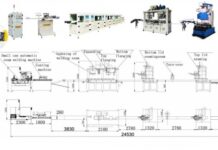

As part of this implementation, the Hushan engineering team carried out a complete integration process–from equipment planning and cleanroom setup to optical calibration, alignment, and mass production validation.

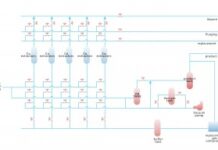

The Active Alignment (AA) technology allows automatic positioning and micro-focus adjustment between the lens and image sensor, precisely minimizing optical-axis deviation and significantly improving image clarity and production consistency.

This technological advancement not only streamlines the manufacturing process but also reinforces Hushan’s commitment to delivering world-class optical assembly quality for the automotive sector.

* Supporting the U.S. CAPA-Certified Aftermarket Lens Market

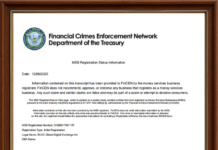

With the AA system fully operational, Hushan is now positioned to serve the high-end CAPA-certified aftermarket lens market in the United States, where optical precision and durability are paramount.

The system ensures each lens meets strict alignment and imaging performance standards, enabling Hushan’s products to comply with CAPA (Certified Automotive Parts Association) requirements for safety, reliability, and optical performance–helping global distributors and service centers deliver OEM-grade replacements to American consumers.

*Integration of Optics and Automation

The AA system’s core strength lies in its seamless fusion of optical measurement and automated control.

Each unit performs real-time image analysis and correction, eliminating manual error while guaranteeing that every lens achieves its optimal optical performance.

All production data are continuously tracked, creating a digital manufacturing record that fulfills the traceability and quality requirements of modern smart factories.

*Integrity, Quality, and Innovation at the Core

Hushan Autoparts continues to advance its long-standing philosophy of Integrity, Quality, and Innovation, focusing on automotive fasteners, optical structural components, and smart automation system integration.

Looking ahead, Hushan plans to expand R&D in automation and AI-driven optical inspection technologies, ensuring stable manufacturing processes and rigorous quality management that meet the evolving needs of global automotive OEM and aftermarket partners.

“Our adoption of the AA Active Alignment System demonstrates Hushan’s determination to deliver precision optical products that meet the highest global standards,” said Mr. Daniel Chen, CEO of Hushan Autoparts Inc. “As the automotive industry evolves toward greater automation and safety, Hushan will continue to invest in advanced manufacturing to support our customers worldwide.

This article was originally published by IssueWire. Read the original article here.