(Isstories Editorial):- Guangzhou, Guangdong Jun 9, 2025 (Issuewire.com) – KLARM Machining, a prominent player in China’s precision engineering landscape, has officially announced a major expansion in its capabilities aimed at supporting the rapidly evolving integrated die casting industry. With the rise of this innovative approach in sectors like automotive, aerospace, consumer electronics, and industrial machinery, the demand for ultra-precise components that can withstand high thermal and mechanical stress is growing at an unprecedented rate. KLARM’s new initiative is specifically tailored to address the complex requirements of integrated die casting machines and the parts they rely on, positioning the company as a key manufacturing partner in this transformative field.

Integrated die casting, often associated with next-generation vehicle production methods and pioneered by industry giants like Tesla, involves the consolidation of multiple parts into a single large aluminum casting. This revolutionary approach improves production efficiency, reduces the number of parts and assembly steps, and enhances structural integrity. However, implementing this technique requires highly specialized die casting machinery capable of maintaining tight tolerances under extreme pressure and temperature conditions. The core components of these machines–including mold bases, ejector systems, plunger tips, cooling elements, and precision dies–must be manufactured with exceptional accuracy and consistency. KLARM’s expansion is specifically designed to meet these challenges.

Eric Sun, General Manager of KLARM, explained the motivation behind this strategic move: “Over the past two years, we’ve witnessed a surge of inquiries from die casting equipment manufacturers and OEMs who are adopting integrated die casting technologies. These partners need parts that are not only dimensionally flawless but also capable of enduring the rigors of high-speed, high-temperature casting cycles. To serve this demand, we’ve invested in new machining infrastructure, enhanced our materials engineering capabilities, and expanded our engineering team with specialists who understand the unique requirements of the die casting sector.”

More on Isstories:

- Daoming Optics – Chemical: Global Leading Reflective Materials Illuminating the Future of Safety and Optical Technology

- Micro Precision Machinery: Global Leading Hydraulic Cylinder Manufacturer Redefining Industrial Motion for 2026

- Dongshuo Fastener: Global Leading Fasteners Manufacturer Redefining Industrial Connectivity for 2026

- Top 5 Benefits of Partnering with ISO 9001 Certified Aluminum Precision Machining Manufacturers

- Future of Superior Transformer Vacuum Drying Oven: Key Industry Insights and Solutions from Transformer Home

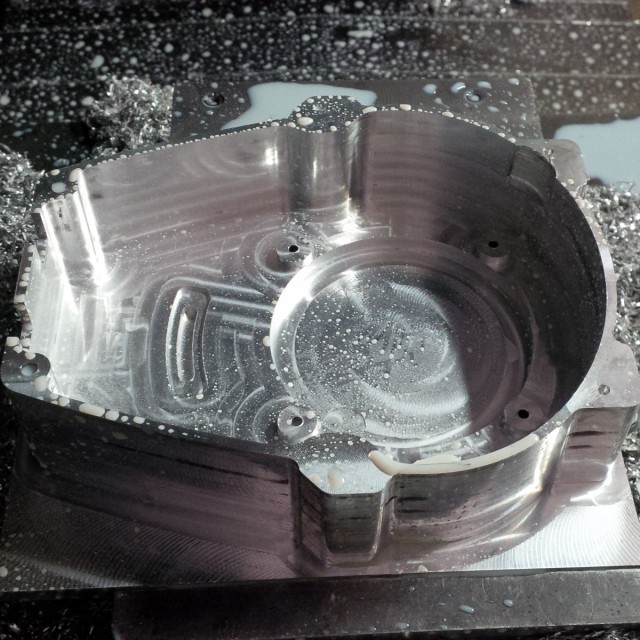

KLARM’s recent investments include advanced 5-axis machining centers, high-speed vertical mills, ultra-precision grinding systems, and wire EDM machines–all calibrated to produce complex geometries in hardened steels, tool steels, and exotic alloys. These materials are essential for die casting machine components, which must resist wear, corrosion, and thermal expansion over millions of cycles. The new equipment allows KLARM to hold tolerances down to the micron level, a critical requirement for mating parts within mold systems and injection units.

Moreover, the company has upgraded its process control systems, including in-line coordinate measuring machines (CMMs), laser scanning inspection tools, and automated statistical process control (SPC) software. These systems allow real-time monitoring of part quality, ensuring that every machined component meets or exceeds client specifications. This is particularly important for components like precision mold inserts, slide cores, and locking mechanisms, where even minor deviations can affect casting performance, cycle time, and product consistency.

Another key focus of the expansion is KLARM’s increased capacity to work with hardened and coated materials that are often used in integrated die casting environments. For example, H13 tool steel, widely used in die casting for its thermal resistance and toughness, presents machining challenges due to its hardness and tendency to work harden. KLARM’s enhanced tooling systems and adaptive control strategies allow efficient machining of these materials while maintaining tool life and part integrity. In addition, the company has partnered with surface treatment providers to offer nitriding, PVD coatings, and thermal spraying for extended component longevity.

KLARM’s deepened capabilities also include the production of large-format components used in integrated die casting setups. The move toward larger and more unified castings in automotive and industrial manufacturing has led to a need for correspondingly larger die tools and machine parts. KLARM has responded by installing large-bed machining centers capable of handling parts over 1.5 meters in length with precision positioning systems that maintain sub-millimeter tolerances across the entire work envelope. This is critical for large mold base plates, tie bars, and complex guiding systems used in giga-press and mega-casting machines.

Furthermore, the company’s engineering team is taking an increasingly collaborative role in customer projects, offering co-design services and manufacturability consulting to optimize component designs for CNC machining services in China. This partnership approach is particularly valuable for die-casting OEMs developing next-generation systems who require rapid prototyping, fast iteration, and input on design parameters such as draft angles, venting geometries, and cooling channel placement. KLARM engineers use advanced CAD/CAM systems and simulation tools to validate designs before machining, reducing lead times and minimizing rework.

In line with its commitment to quality and innovation, KLARM is also building out a dedicated application engineering group to support integrated die casting projects. This team is composed of mechanical engineers, materials scientists, and tooling experts who bring domain-specific knowledge to customer collaborations. Whether it’s solving heat dissipation issues in mold inserts, enhancing ejection force efficiency, or developing hybrid material solutions, the group is positioned to accelerate development timelines and ensure performance in real-world production environments.

The expansion also reflects KLARM’s strategic vision to serve industries undergoing rapid digital and structural transformation. The shift toward integrated die casting is part of a broader trend of simplification, automation, and material efficiency in manufacturing. As products become more consolidated and design cycles shorten, the demand for high-precision machining factory in China that supports this evolution will only intensify. KLARM sees itself not just as a supplier, but as a strategic enabler for companies seeking to transition from traditional assembly-intensive manufacturing to leaner, casting-based approaches.

Already, the company has secured partnerships with Tier 1 suppliers in the automotive sector, machine builders developing proprietary casting platforms, and R&D centers exploring new alloy systems and cooling methods. These collaborations are bearing fruit in the form of rapid turnaround on prototype components, support for test bench systems, and production runs of critical wear parts. In several cases, KLARM’s precision components have enabled customers to extend tool life, reduce maintenance intervals, and improve casting surface quality–all while keeping costs under control.

Looking ahead, KLARM plans to deepen its integration with die casting system providers through digital twin integration and predictive maintenance feedback loops. By incorporating sensor-enabled machined parts and partnering with OEMs on smart system design, KLARM envisions a future where every high-precision component it delivers contributes to a more efficient, adaptive, and data-driven casting ecosystem.

This latest capability expansion confirms KLARM’s long-term commitment to staying at the forefront of advanced manufacturing and high-precision engineering. As the needs of the integrated die casting sector continue to grow in complexity and scale, KLARM is positioned not just to meet the challenge but to help shape the direction of the industry itself.

Klarm Group Limited

*****@gmail.com

Lanny Larm

Panyu, Guangzhou, Guangdong, China

http://www.cncmachinings.com

This article was originally published by IssueWire. Read the original article here.