Brewflex, a trusted Australian supplier of sanitary process equipment, is reinforcing its commitment to performance with a specialised line of silicone and rubber o rings developed to meet the intense demands of food&beverage production environments.

More on Isstories:

- Pro-Line Trailers to Exhibit at MDA Car Show 2026

- COAST: The China Smart Glass Film Manufacturer Bridging Aesthetics and Energy Efficiency

- A Professional Guide to Choosing a High Quality Rare Earth Heat Blocking Window Film Manufacturer

- Scientist-Turned-Seeker Reframes Ancient Wisdom in Echoes from a Spiritual Name

- Empowering Green Buildings: China Smart Glass Film Manufacturer Providing Sustainable Privacy Solutions

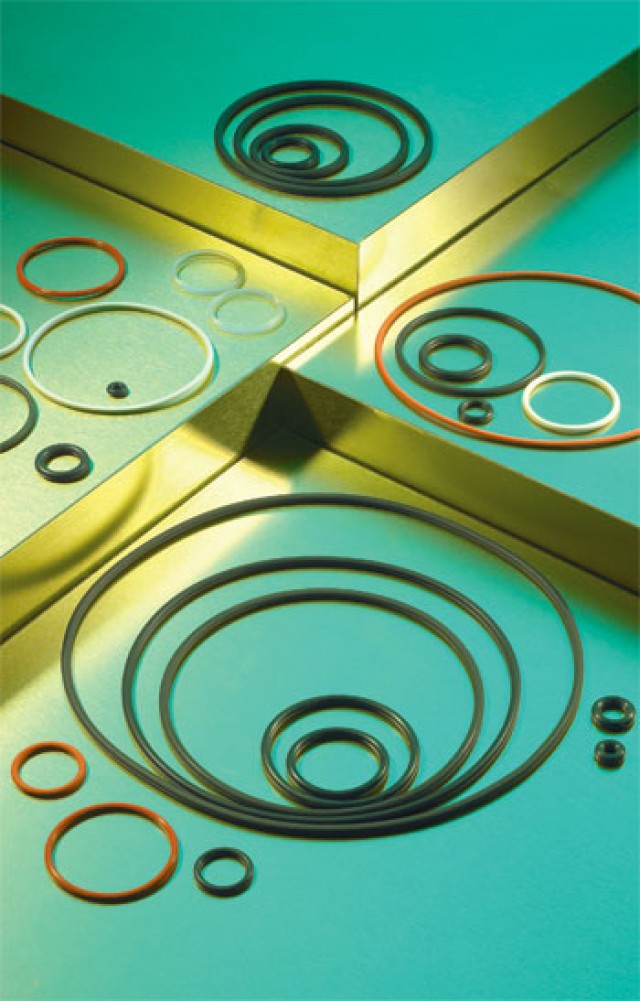

(Isstories Editorial):- Bayswater, Victoria Jun 3, 2025 (Issuewire.com) – Brewflex, a trusted Australian supplier of sanitary process equipment, is reinforcing its commitment to performance and reliability with a specialised line of silicone o rings and rubber o rings developed to meet the intense demands of food, beverage and brewery production environments. Known for its high standards in engineering, Brewflex delivers sealing solutions that combine hygienic design with exceptional resilience in high-pressure and high-temperature applications.

These o-rings are a vital part of modern process systems, serving as the first line of defence against leaks, contamination and system failure. By offering high-specification options in a variety of compounds, Brewflex helps ensure that critical seals perform consistently–no matter how complex or rigorous the production line.

Tailored for Sanitary and Industrial Use

Brewflex’s silicone o rings are manufactured using platinum-cured compounds, offering a smooth, non-stick surface and excellent elasticity. They are ideal for applications where thermal variation and non-reactive materials are essential, such as CIP (Clean-In-Place) and SIP (Sterilise-In-Place) routines. Their non-leaching nature makes them especially suitable for systems processing sensitive or high-purity ingredients.

The company’s rubber o rings, including Buna-N and Viton variants, are engineered to withstand exposure to oils, cleaning chemicals and high mechanical stress. These seals are frequently used in pump housings, valve assemblies, tri-clamp connections and tank fittings, offering long-term resistance to compression set, tearing and abrasion.

Both o-ring types are available in a wide range of sizes and hardness levels, compatible with stainless steel connections and food-grade tubing systems commonly used in Australian breweries, distilleries and food processing facilities.

Part of a Broader Equipment Ecosystem

These sealing solutions are designed to integrate seamlessly with Brewflex’s full suite of process equipment. The company supplies everything from diaphragm valves, CIP pumps and carbonation stone assemblies to brite tanks, fermenters and heat exchangers. All components are built with a focus on hygiene, efficiency and compatibility.

Brewflex also provides value-added services that help ensure seamless operation and long-term system performance. This includes custom fabrication, laser etching for part identification, equipment commissioning, and routine hose audits. With this comprehensive approach, the company helps clients build and maintain reliable process systems from the inside out.

Built to Support Production Without Compromise

In the fast-paced world of beverage and food manufacturing, equipment failure isn’t an option. Brewflex’s silicone o rings and rubber o rings are part of a carefully selected range of system-critical components, built to support uptime, cleanliness and compliance. By delivering sealing solutions that stand up to both operational stress and regulatory standards, Brewflex continues to support Australian businesses striving for consistency, safety and product excellence.

Source :Brewflex Australia

This article was originally published by IssueWire. Read the original article here.