(Isstories Editorial):- Guangzhou, Guangdong Apr 15, 2025 (Issuewire.com) – KLARM, a leading precision CNC machining and advanced manufacturing company in China, is proud to announce a major expansion of its technological capabilities, infrastructure, and strategic focus to support the emerging and rapidly advancing quantum industry chain. With quantum technologies gaining momentum across computing, communications, sensing, and cryptography, the company is positioning itself as a critical player in supplying the ultra-precise, high-performance components that form the physical foundation of the quantum revolution.

This strategic move comes in response to growing global interest in quantum technologies, not only from academic research institutions and government laboratories but also from commercial enterprises investing heavily in quantum computing hardware, cryogenic systems, quantum sensors, and photonic infrastructure. As these technologies transition from scientific exploration to industrial development and commercial deployment, there is an escalating demand for components with extreme dimensional accuracy, material integrity, and environmental stability. KLARM recognizes the unique role precision machining plays in this transformation and is committed to becoming a trusted partner for companies and institutions involved in building the next generation of quantum-enabled devices and infrastructure.

More on Isstories:

- A Fragrance Made for Self-Expression and Identity: Anvera Introduces Origin 0.1 in India

- The Architecture of Taste: Helen Yi and a Deliberate Vision of Luxury

- Data, Not Desperation: How Leslie Wise Is Redefining Grant Strategy to Drive Real Community Impact

- Dr. Santosh Kumar Guptha Highlights ICD-11 as the Future of Healthcare Data at MEDRECON 2026

- Sacramento Aesthetic Surgery Unveils High Extended SMAS Facelift by Expert Dr. Hause for Natural Rejuvenation

At the core of the quantum industry’s development is an increasingly complex hardware ecosystem. Quantum computing, for instance, relies on qubits–quantum bits–which can be realized through various architectures, including superconducting circuits, trapped ions, neutral atoms, photonic systems, and spin-based devices. Regardless of the approach, these platforms share a common requirement: an environment of unparalleled physical precision and stability. This necessity extends to every layer of the hardware stack, from vacuum chambers and cryostats to micro-optomechanical systems and ultra-low-loss enclosures. KLARM’s expanded capabilities now directly address the stringent demands of this ecosystem by delivering the fine-tuned components essential to enabling quantum coherence, noise isolation, and precision signal control.

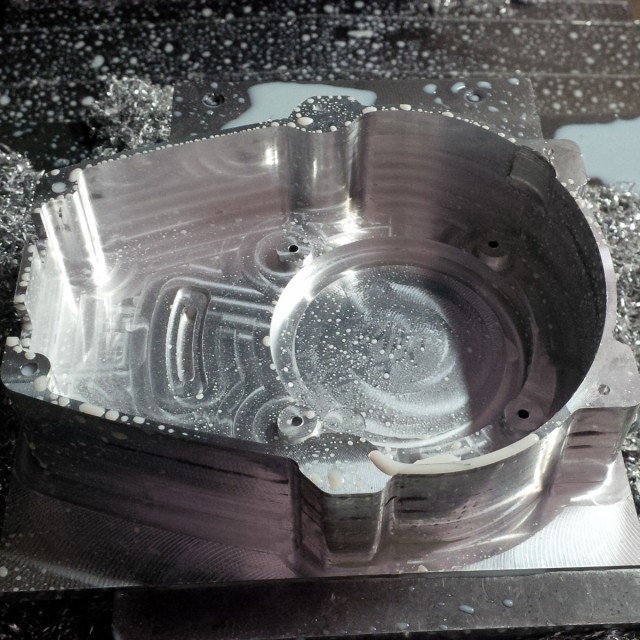

In support of this shift, KLARM has invested in a new generation of high-performance CNC machines, capable of achieving tolerances in the sub-micron range and surface finishes down to nanometer-level roughness. These capabilities are essential for manufacturing components such as optical mounts, vacuum-compatible feedthroughs, electromagnetic shielding enclosures, and mechanical assemblies for dilution refrigerators–all of which must operate reliably under extreme environmental conditions, including ultra-low temperatures, high vacuum, and electromagnetic isolation. In addition to precision 5 axis machining, KLARM has enhanced its capacity for ultra-clean assembly, advanced inspection and metrology, and traceable quality documentation in accordance with aerospace, defense, and scientific research standards.

This expansion is not simply a technical upgrade–it is the result of a strategic commitment to becoming part of a transformative global industry. Quantum technologies are projected to impact a broad array of sectors including national defense, secure communications, materials discovery, pharmaceuticals, finance, and artificial intelligence. The realization of these opportunities requires a robust and agile supply chain capable of delivering both innovation and consistency. KLARM understands that its value to the quantum industry lies not only in its ability to manufacture precision components, but also in its flexibility, speed, and collaborative approach to product development. The company has already begun working closely with research laboratories, quantum computing startups, and system integrators, offering design-for-manufacturing guidance, prototyping services, and iterative component development tailored to the unique needs of quantum hardware engineering.

The convergence of multiple disciplines–physics, materials science, electronics, optics, and cryogenics–within the quantum industry creates highly interdisciplinary requirements for component manufacturing. KLARM’s cross-functional engineering team, comprised of experts in mechanical design, materials analysis, and high-precision metrology, is now fully equipped to support these multidisciplinary challenges. Whether the task involves minimizing mechanical resonance in an ion trap frame, machining superconducting materials without compromising phase integrity, or ensuring dimensional consistency in optical cavities subjected to cryogenic cycling, KLARM delivers a level of expertise and craftsmanship that meets the exacting standards of quantum systems engineering.

Beyond the mechanical demands, the quantum industry also places unique requirements on materials. Many components must be fabricated from metals and alloys that exhibit low magnetic susceptibility, excellent thermal conductivity, and high resistance to outgassing–such as oxygen-free high conductivity (OFHC) copper, niobium, titanium, aluminum alloys, and stainless steels with controlled magnetic properties. KLARM has refined its machining processes to work with these materials, preserving their structural and surface integrity throughout the production cycle. The company also adheres to strict cleaning and contamination control protocols, ensuring that parts delivered for use in quantum devices meet ultra-high vacuum (UHV) compatibility and low-temperature performance standards.

The integration of photonics into quantum computing and communication systems has added another layer of complexity to hardware development. KLARM is actively supporting this area by producing high-precision mounts and alignment systems for lasers, beam splitters, mirrors, and fiber-optic components. These parts must not only achieve tight dimensional control but also maintain optical alignment over time despite thermal and mechanical disturbances. With photonic quantum computing gaining traction as one of the most promising architectures for large-scale systems, the demand for these specialized mechanical components is expected to grow exponentially. KLARM is already scaling its production workflows to support both custom and high-volume needs in this space.

As part of its commitment to the quantum sector, KLARM is also pursuing certifications and quality system enhancements aligned with the needs of research and mission-critical hardware supply chains. The company is working toward ISO 9001 and ISO 13485 certifications, and plans to implement advanced traceability systems to meet documentation and reproducibility standards required by quantum technology developers, government agencies, and scientific institutions. KLARM’s internal R&D efforts are focused on further refining toolpath algorithms, thermal deformation prediction, and vibration isolation during machining–critical for achieving the ultra-consistent quality levels required for quantum-grade hardware.

According to Jacky, CEO of KLARM, this expansion reflects not just a business decision, but a broader vision for contributing to the future of science and technology. “We see quantum technology as one of the most profound and far-reaching advancements of our era. Its potential to reshape computing, communication, and sensing is extraordinary. But none of that can happen without physical systems that meet the highest possible standards of precision and reliability. Our mission is to provide the mechanical foundation on which this new era can be built.”

Looking forward, KLARM is also exploring opportunities to collaborate with academic institutions, national research facilities, and international quantum research initiatives. By offering support for proof-of-concept projects and early-stage hardware experiments, the company aims to help researchers transition more efficiently from the lab to scalable, manufacturable solutions. KLARM believes that by working closely with the innovators at the cutting edge of quantum science, it can remain aligned with the evolving technical challenges and help accelerate the commercialization of quantum technologies worldwide.

As the quantum industry continues to evolve from theoretical promise to technological reality, the demand for precision manufacturing will only intensify. KLARM’s expanded capabilities, deep engineering expertise, and collaborative spirit make it uniquely suited to meet the current and future needs of this emerging field. The company is not merely watching the rise of quantum technologies–it is building the physical components that will help make them possible.

KLARM Precision Machining is a China-based leader in advanced CNC Swiss machining, complex component manufacturing, and custom fabrication for high-tech industries. The company serves clients across aerospace, medical, robotics, automation, green energy, and now, the quantum technology sector. With state-of-the-art machinery, a world-class engineering team, and a reputation for precision, reliability, and innovation, KLARM supports cutting-edge companies and institutions in transforming bold ideas into real-world breakthroughs.

Klarm Group Limited

*****@gmail.com

Lanny Larm

Panyu, Guangzhou, Guangdong, China

http://www.cncmachinings.com

Source :Klarm Group Limited

This article was originally published by IssueWire. Read the original article here.